The KTM-A14 Multifunctional UV Flatbed Printer represents a significant advancement in direct-to-substrate printing technology. This cutting-edge device utilizes ultraviolet (UV) light to cure specially formulated inks directly onto a wide variety of materials, opening up a world of possibilities for personalized customization and high-quality prints. Understanding its underlying mechanics reveals the true power and versatility of this UV flatbed printer.

At the heart of the KTM-A14 lies its sophisticated print head system. Depending on the configuration, it operates with either dual i1600-U1/i3200-U1 print heads or three i1600-U1 print heads. These piezoelectric inkjet print heads are responsible for precisely depositing the UV-curable ink onto the substrate. Piezoelectric technology utilizes the principle of piezoelectricity, where certain crystals generate an electric charge in response to applied mechanical stress. In the print heads, this effect is harnessed to control the ejection of ink droplets with remarkable accuracy. Each droplet is meticulously placed, contributing to the printer's impressive resolution of up to 2400 dpi. This high resolution allows for crisp, detailed images and vibrant colors, making the KTM-A14 a powerful tool for producing high-quality prints on various media. This precision is particularly valuable in applications requiring fine details, such as photographic reproductions or intricate graphic designs. The versatility of the KTM-A14 as a UV flatbed printer is further enhanced by its ability to handle a wide gamut of substrates.

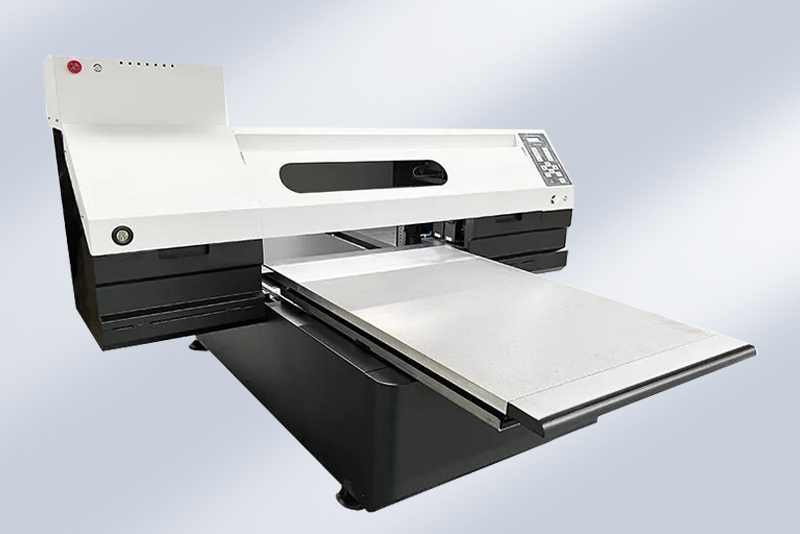

The KTM-A14 UV flatbed printer boasts a generous printing width of 600x900mm, accommodating a variety of substrate sizes. It can handle materials up to 600mm wide and an impressive 180mm thick, allowing for printing on objects ranging from thin sheets to thicker, more substantial items. This broad compatibility makes the KTM-A14 suitable for diverse applications, including signage, promotional items, personalized gifts, and even industrial part marking. Imagine printing directly onto phone cases, wood planks, acrylic sheets, or even ceramic tiles – the KTM-A14 UV flatbed printer makes it all possible.

The ink system of the KTM-A14 is another key component contributing to its versatility. It employs a color siphon system with regular mixing of white ink, ensuring consistent color accuracy and preventing sedimentation. The W+CMYK+Varnish ink configuration provides a wide color gamut and the option for a protective varnish layer, adding durability and a professional finish to the prints. The inclusion of white ink allows for vibrant prints on darker substrates and opens up possibilities for unique design elements. The varnish adds a layer of protection and enhances the visual appeal, making the prints resistant to scratches and fading.

A crucial aspect of any UV flatbed printer is the curing process. The KTM-A14 utilizes dual UV LED lights to instantly cure the ink as it is deposited onto the substrate. This UV curing process offers several advantages over traditional drying methods. It eliminates the need for lengthy drying times, allowing for immediate handling and further processing of the printed materials. Furthermore, UV curing ensures the ink adheres strongly to the substrate, resulting in highly durable and scratch-resistant prints. The rapid curing also minimizes the risk of ink bleeding or smudging, contributing to the overall sharpness and quality of the output. This makes the KTM-A14 a highly efficient UV flatbed printer, ideal for high-volume production.

The speed of the KTM-A14 UV flatbed printer is equally impressive. It can complete an A2 sheet at 720x900 dpi in as little as 5 minutes, demonstrating its efficiency for both small-scale and larger production runs. This speed, combined with the instant curing of the UV ink, allows for rapid turnaround times, a critical factor in many commercial printing environments. The printer is equipped with a Gigabit Ethernet interface for seamless connectivity and efficient data transfer.

Powering this sophisticated UV flatbed printer is a 1300W power supply operating on AC220V. The printer's dimensions, including the stand, are 1580 x 1380 x 960 mm, making it a substantial piece of equipment. Despite its size, the KTM-A14 is designed for ease of use and maintenance.

In conclusion, the KTM-A14 Multifunctional UV Flatbed Printer stands as a testament to the advancements in digital printing technology. Its combination of high-resolution piezoelectric print heads, a versatile ink system, efficient UV LED curing, and robust construction makes it a powerful tool for a wide range of printing applications. This UV flatbed printer offers businesses and individuals alike the opportunity to create high-quality, personalized prints on a vast array of materials, unlocking new levels of creativity and customization. From promotional items and signage to personalized gifts and industrial applications, the KTM-A14 redefines the possibilities of direct-to-substrate printing.