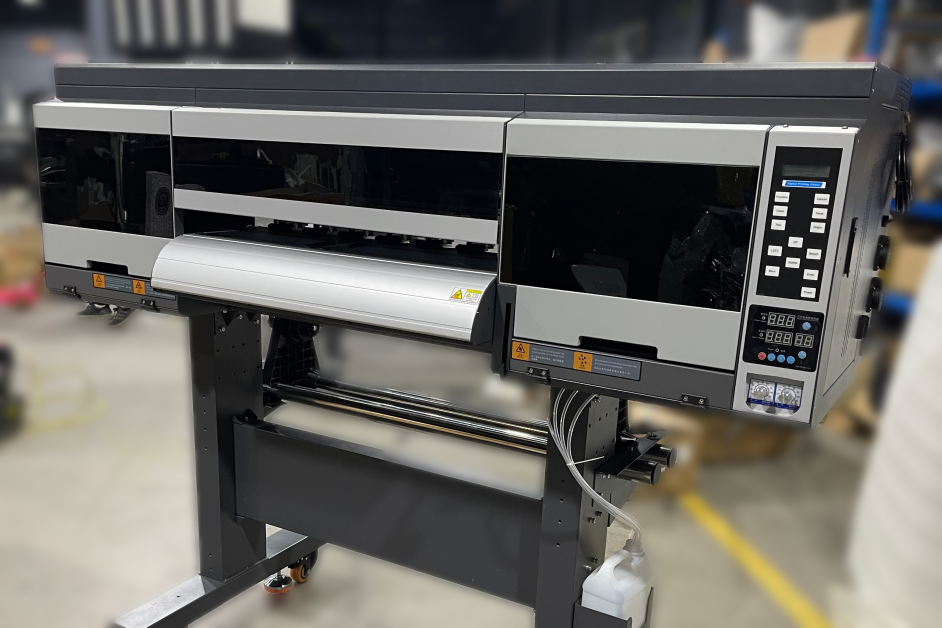

DTF printing has emerged as a groundbreaking technology in the textile industry, offering unparalleled versatility and quality. Among the leading DTF printers is the Kenteer KTM-A09, a cutting-edge machine that has garnered significant attention for its exceptional performance and wide range of applications.

The versatility of the KTM-A09 extends across various industries and applications. In the textile industry, it is ideal for printing on a wide range of fabrics, including cotton, polyester, and blends. From T-shirts and hoodies to bags and accessories, the KTM-A09 can handle a variety of textile substrates.

Beyond textiles, the printer's applications also include promotional products, home decor, and footwear. It can be used to create customized mugs, phone cases, keychains, pillows, curtains, and sneakers. The ability to print on diverse materials makes the KTM-A09 a valuable asset for businesses in various sectors.

DTF Printing Process

The DTF printing process involves several key steps:

1. Ink Transfer: The printer applies specialized textile pigment ink onto a transfer film.

2. Powder Application: A layer of powder is evenly distributed over the wet ink to create a solid film.

3. Curing: The film is cured in a heat press to bond the ink and powder.

4. Application: The cured film is applied to the desired textile substrate and heat-pressed again to transfer the design.

The Kenteer KTM-A09 DTF Printer is a powerful and versatile tool that has the potential to revolutionize the textile industry. With its exceptional print quality, wide range of applications, and ease of use, the KTM-A09 is an ideal choice for businesses seeking to create high-quality, customized products. As DTF printing technology continues to evolve, the KTM-A09 is poised to play a leading role in shaping the future of textile production.

If you have product purchasing needs, you can contact us.