In the heat transfer printing market, there are many heat transfer materials. The same product has different names in different regions, and the same series of thermal transfer materials also have many product numbers. Today let me share with you the basic knowledge of common heat transfer materials: heat transfer vinyl, PET release film, and heat transfer sticker.

1. Heat transfer vinyl

Heat transfer vinyl is a high-tech material for digital printing applied to heat-resistant textiles. Usually monochrome (except for printable lettering film that can be engraved with multi-color patterns), it is mainly used for printing numbers on sportswear, or engraving personalized patterns on fashion clothing. The lettering film is used for personalized customization, no need to open the plate, and it will be ready in 10 minutes.

We produce it by coating technology. Besides we produce many types with different effects based on customers’ requirements, such as solid color, glitter effect, hologram effect, metallic effect, flock effect, reflective effect, glow in the dark effect heat transfer vinyl, etc.

It is very easy to use, as long as you have a computer, cutting plotter, and heat press machine. First, make the design on the computer, then cut by cutting plotter or laser cutting machine, then weeding, then transfer the design on the fabric via heat press machine.

2. PET release film

PET release film is divided into cold peeling and hot peeling PET film, suitable for water-based/oil-based screen printing inks of various levels of heat transfer products, heat transfer with various characteristics, heat transfer printing substrates,

etc. The release film on the market can be customized into finished rolls and slitting and packaging into sheets. The main function of the release film is for peeling, anti-adhesion, and anti-static.

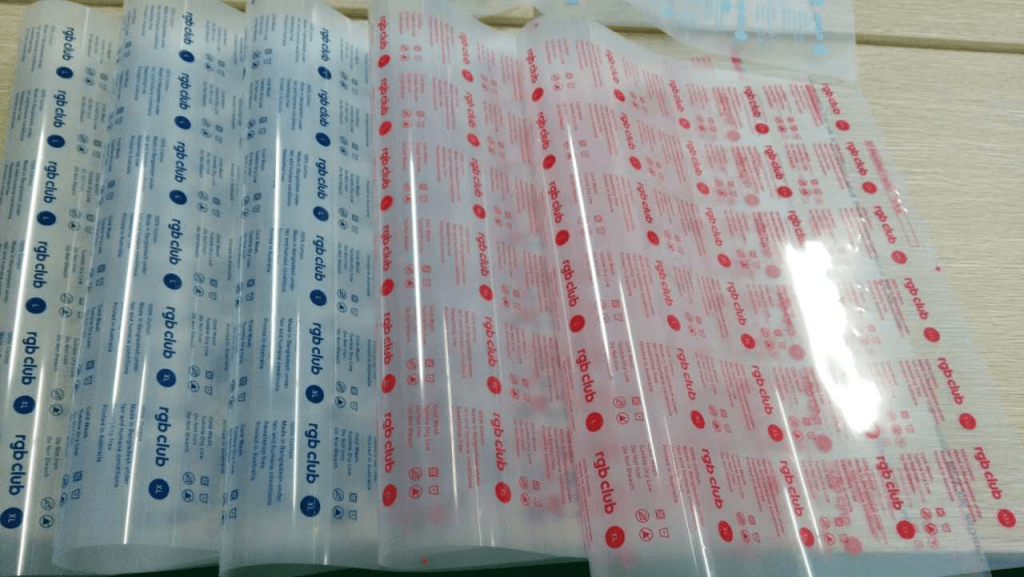

Heat transfer sticker

Heat transfer sticker is a customized product, and the type of heat transfer is confirmed according to customer needs, and detailed requirements such as heat transfer fabrics, washing fastness, and environmental protection are confirmed at the same time. Heat press can be one MOQ or bulk order. Heat press has clear and delicate images, soft and smooth feel, and is easy to operate. It is a new product in the 1990s and differs from traditional printing.

We produce them in different effects based on customers’ other requirements, such as elastic effect, soft effect, anti-sublimation effect, care label, flock effect, reflective effect, silicone effect, etc.

We have total 21 automatic printing lines and we produce chemicals for our printing.

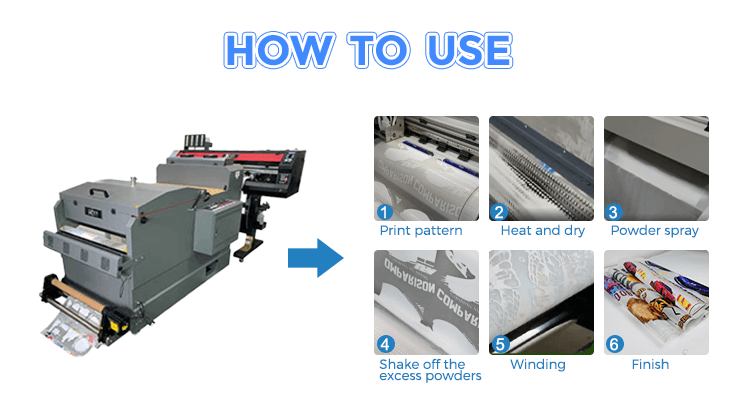

DTF printing materials

DTF stands for 'direct-to-film' in printing. DTF printing is a new type of printing technology that has become popular all over the world in recent years. Because of its advantages of no weeding, no waste, and no need for set-up making, it subverts the traditional printing process, and DTF printing has become popular in the printing industry.

The principle of DTF printing is to print the pattern on dtf film and then transfer the pattern on the film to various fabrics after being pressed by a heat press machine. DTF printing is eco-friendly and pollution-free and meets the national environmental protection requirements.

What is even more commendable is that the actual color effect of dtf printing can exceed the actual effect of photos. Not only are the colors bright and the visual three-dimensional effect is strong, but also it has high washing fastness, which is not easy to fade after repeated washing, and is resistant to shrinkage and stretching. It is no wonder that dtf printing is one of the new garment printing techniques recognized by various garment enterprises in the past two years.

DTF printing equipment mainly includes printers, a powder spray powder machine, and a heat press machine. DTF printing can be printed in one piece or batches, with flexible inventory control, suitable for small-batch web orders and personalized customization. DTF printing equipment has a low investment threshold and low cost, which is the first choice for a small investment and large return.

Finally, a total set of dtf printing materials include dtf film, dtf ink, and dtf powder. We can provide all of them to save our customers’ purchasing time costs.

With our expertise in heat transfer printing, kenteerfilm can provide traditional screen and offset printing or DTF printing solutions that are tailored to your specific needs, whether it’s your machines, inks, or production processes