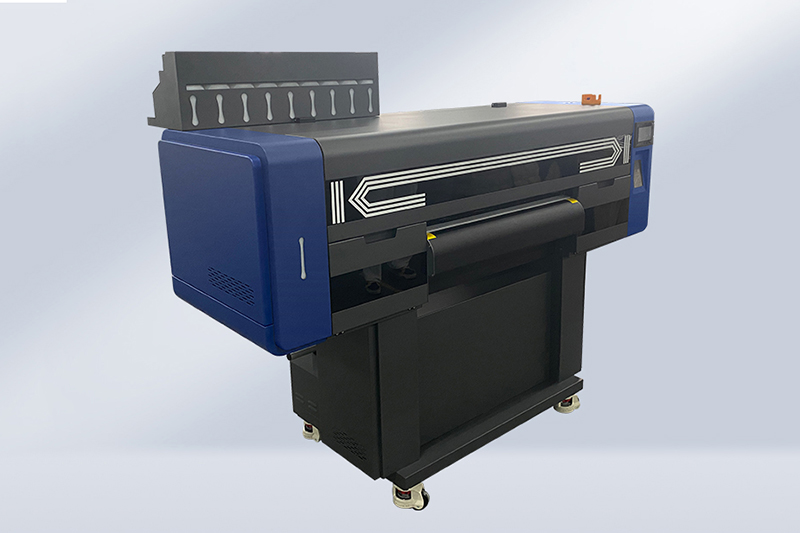

The world of direct-to-film (DTF) printing is rapidly evolving, offering new possibilities for apparel and product customization. At the forefront of this innovation stands the KTM-A41 DTF Printer, a machine engineered for exceptional performance and versatility. This article delves into the technical specifications of the KTM-A41, exploring its features and functionalities to understand why it's a compelling choice for businesses seeking to expand their printing capabilities.

Built for Precision and Durability

The KTM-A41 boasts a robust construction with a stable THK guide rail system. This high-quality component ensures smooth and precise print head movement, minimizing vibrations and contributing to exceptional printing accuracy. Additionally, the printer features intelligent temperature control, a crucial factor for maintaining consistent ink viscosity and optimal color reproduction throughout the printing process. This intelligent system translates to longer service life for the print heads and overall printer components.

Enhanced Ink Flow and Uninterrupted Printing

The KTM-A41 incorporates a multifaceted approach to ensuring seamless ink delivery and preventing printing interruptions. The upgraded damper heating system plays a vital role. By maintaining a consistent temperature, the dampers promote optimal ink fluency, guaranteeing a steady flow of ink to the print heads. This translates to stable and consistent output, reducing the likelihood of printing inconsistencies or errors.

Furthermore, the printer employs nozzle-height compensation technology. This intelligent system automatically adjusts the distance between the print heads and the printing media, effectively compensating for any inconsistencies in media thickness. This ensures consistent ink application across the entire print surface, regardless of minor variations in media height.

Maintaining Print Quality and Efficiency

The KTM-A41 prioritizes print quality and production efficiency through its innovative features. The auto in-line moisturizing function actively combats nozzle clogging, a common challenge in DTF printing. By introducing a precise amount of moisture at specific intervals, the printer prevents ink buildup within the nozzles, minimizing the risk of interruptions and ensuring consistent print quality.

Exceptional Print Capabilities

The KTM-A41 is equipped with the Epson I3200-A1 print head, renowned for its accuracy and reliability. This industrial-grade print head is available in configurations with two, four, or five heads, allowing users to tailor the printing speed and capacity to their specific needs. The printer utilizes piezoelectric inkjet technology, a method known for producing sharp details, vibrant colors, and smooth tonal transitions.

The KTM-A41 offers a maximum print width of 600mm, accommodating a wide range of printing applications. Whether you're customizing t-shirts, phone cases, or other products, the printer provides ample capacity for handling various project sizes. Additionally, the printer supports a broad spectrum of media with a maximum thickness of 1mm, ensuring compatibility with most DTF transfer films.

Color Management and Media Compatibility

The KTM-A41 prioritizes color accuracy and user control. The printer supports ICC color profiles and density curve adjustments, empowering users to achieve consistent color reproduction and match specific color requirements. This level of control is particularly valuable for businesses working with brand guidelines or specific color palettes.

The KTM-A41 seamlessly integrates with various RIP software options, including Maintop, Photoprint, and CalderaRIP. These software programs enable users to manage print jobs, edit images, and perform color adjustments before sending the final design to the printer. This streamlined workflow optimizes the printing process and ensures exceptional results.

Additional Features

The KTM-A41 is equipped with an RJ-45/LAN interface, facilitating network connectivity and remote printing capabilities. This allows for greater flexibility in managing print jobs and integrating the printer into existing production workflows.

The printer operates on a standard power supply of 50HZ/60HZ and supports both 110V and 200V voltages, ensuring compatibility with most electrical grids around the world. The optimal operating environment for the KTM-A41 is a temperature range of 20℃ to 28℃ and a humidity level between 65% and 75%. Maintaining these conditions is crucial for ensuring optimal print quality and performance.

If you have product purchasing needs, you can contact us.