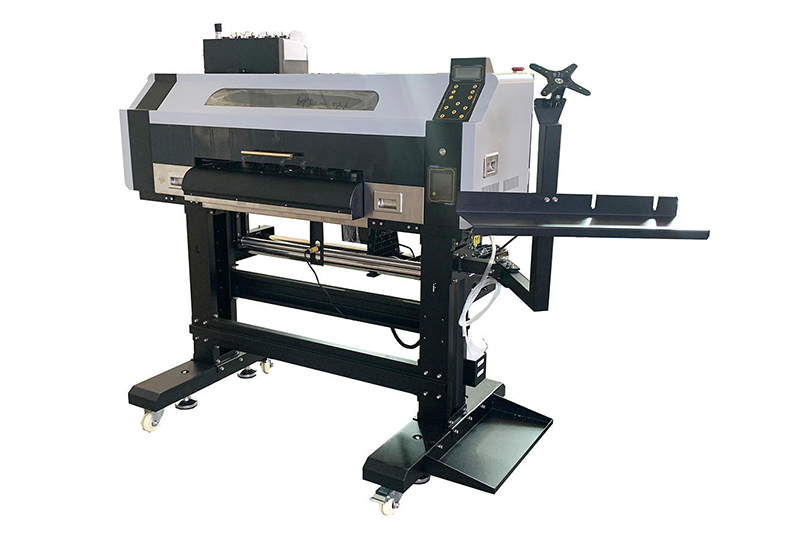

The KTM-60602 DTF Printer is a state-of-the-art device designed to deliver high-quality, vibrant prints on a wide range of materials. To ensure optimal performance and longevity, a regular maintenance routine is essential. This guide will provide you with detailed instructions on how to care for your DTF printer.

Understanding the DTF Printing Process

Before delving into maintenance, it's crucial to have a basic understanding of how a DTF printer works. The KTM-60602 utilizes a direct-to-film printing process, where ink is directly deposited onto a PET film. This film is then transferred to the desired substrate using heat and pressure.

Daily Maintenance

Inspect the Print Head: Regularly check the print head for any signs of clogging or damage. Use the printer's built-in cleaning function to remove any debris.

Clean the Platform: Keep the printing platform clean and free of any ink or debris. Use a soft, lint-free cloth dampened with distilled water to clean the surface.

Check Ink Levels: Monitor the ink levels in each cartridge and refill as needed. Using high-quality DTF inks is essential for producing vibrant and long-lasting prints.

Clean the Waste Ink Bottle: Empty the waste ink bottle regularly to prevent overflow.

Weekly Maintenance

Deep Clean the Print Head: Perform a deep cleaning of the print head using the printer's maintenance software. This will help to remove any stubborn clogs or residue.

Calibrate the Printer: Calibrate the printer to ensure accurate color reproduction and alignment.

Check the Heating System: Verify that the front and rear arc plate heating and platform suction systems are functioning correctly.

Monthly Maintenance

Inspect the Belts and Rollers: Check the belts and rollers for wear and tear. Replace any damaged components.

Clean the Interior: Clean the interior of the printer to remove any dust or debris.

Update Firmware: Keep the printer's firmware up-to-date to benefit from the latest features and bug fixes.

Preventative Maintenance

Use Filtered Air: Operate the printer in a clean, dust-free environment. Use an air purifier to remove contaminants from the air.

Regular Power Cycling: Power cycle the printer periodically to reset any temporary errors.

Avoid Sudden Power Outages: Protect the printer from sudden power outages by using a surge protector.

Troubleshooting Common Issues

Clogged Print Head: If you notice streaks or banding in your prints, the print head may be clogged. Perform a deep cleaning or contact a technician for assistance.

Poor Adhesion: If the ink is not adhering to the transfer film, check the ink settings, film quality, and curing temperature.

Color Mismatch: A color mismatch can be caused by incorrect color profiles, fading inks, or a dirty print head.

Paper Feed Issues: Paper feed issues can be caused by a variety of factors, including paper jams, dirty rollers, or incorrect paper settings.

By following these maintenance tips, you can significantly extend the lifespan of your KTM-60602 DTF Printer. Regular maintenance will help to prevent costly repairs and downtime.

If you have product purchasing needs, you can contact us.