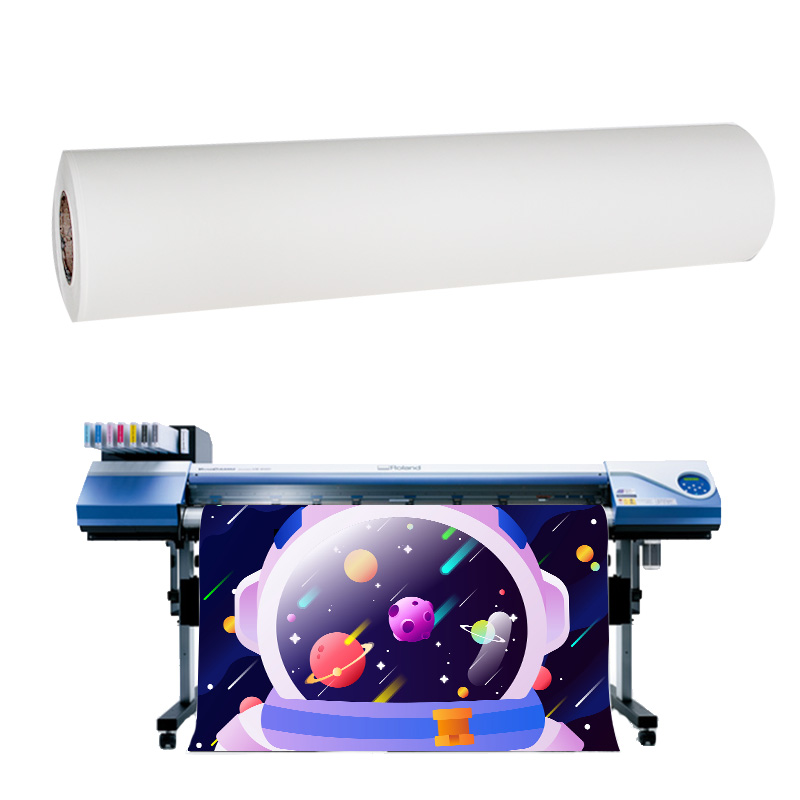

Heat transfer sublimation paper plays a vital role in the sublimation printing process to transfer vibrant, high-quality designs to a variety of substrates. However, not all sublimation papers are created equal. In this article, we explore the different types of sublimation papers for sublimation transfer, discuss their variations, and provide insights on how to choose the right paper for different industries and applications.

Standard sublimation paper

Standard dye-sublimation paper is the most commonly used type and is suitable for a wide range of applications. It has a special coating that aids in the transfer of sublimation dyes to polyester based materials such as fabrics, ceramics and metals. It offers good ink absorption, image clarity and color vibrancy, making it a solid choice for general sublimation printing needs.

Quick dry sublimation paper

Fast drying sublimation paper is designed to optimize production efficiency. It features an advanced coating that promotes fast ink drying for faster print speeds and shorter production times. This type of paper is especially suitable for industries that require high-volume printing, such as textile manufacturing or the production of promotional products.

Adhesive sublimation paper

Adhesive sublimation paper, also known as adhesive sublimation paper, has a slightly sticky surface. This adhesive property helps prevent the transfer paper from shifting during the thermal transfer process, ensuring accurate image alignment. It is often used when printing on elastic or stretchable fabrics, as it helps keep the image in place without causing distortion.

Hybrid sublimation paper

Hybrid sublimation paper is specially designed for direct and indirect sublimation process. It is versatile, allowing the user to transfer the design directly to the substrate or use it as a transfer medium onto another sublimation paper before transferring the image to the final substrate. This type of paper benefits industries that require flexibility in the printing process.

Precautions for choosing sublimation paper in different industries

Clothing and Textile Industry

In the apparel and textile industries, choose dye-sublimation papers with excellent color reproduction, sharp image details and good ink absorption. Consider the fabric type, whether natural or synthetic, as certain papers may perform better on specific materials. Also, for high-volume production, fast-drying sublimation paper can significantly increase productivity.

Signage and Advertising Industry

For large-format prints and outdoor signage, choose sublimation papers with high ink saturation and excellent resistance to UV fading and environmental factors. Look for papers that offer a wide color gamut and good ink release to ensure vivid, long-lasting prints.

Home decoration and gift industry

When making items like mugs, coasters or decorations, choose a sublimation paper for ceramic, metal or other specific substrates. Adhesive sublimation paper helps maintain precise image placement, especially for irregularly shaped or curved objects.

Sports and Sportswear Industry

In sportswear, durability and breathability are crucial factors. Look for sublimation papers that have excellent color retention, are abrasion resistant, and allow the fabric to retain its breathability. Consider using hybrid dye-sublimation papers for the flexibility of direct or indirect transfers based on specific garment requirements.

Choosing the right sublimation paper for sublimation printing is essential to achieve the best results in sublimation printing in various industries. Consider the specific needs of your industry, such as fabric type, yield, durability and substrate compatibility. Know the Difference Between Standard, Fast Dry, Tacky and Hybrid Dye Sublimation Papers.