DTF printing has gained popularity in the custom apparel industry, providing small businesses with the ability to create high-quality, customized prints. When it comes to choosing a DTF printer, it's important to understand the different types available and select the one that best suits your business needs. In this article, we will explore the various types of DTF printers, their differences, and how to choose the right one for your small business.

1. Roll-to-Roll DTF Printer:

Roll-to-roll DTF printers are designed to print on continuous rolls of film, allowing for efficient and high-volume production. These printers are ideal for small businesses that have a consistent demand for custom apparel. Roll-to-roll DTF printers offer fast printing speeds and can handle larger print sizes, making them suitable for businesses that require large-scale production. They are versatile and can print on various fabrics, providing flexibility in product offerings.

2. Sheet-fed DTF Printer:

Sheet-fed DTF printers are designed to print on individual sheets or pre-cut pieces of film. These printers are suitable for small businesses that have smaller production volumes or require more flexibility in printing different designs or sizes. Sheet-fed DTF printers are compact and easy to use, making them a popular choice for businesses with limited space or for those just starting in the custom apparel industry. They offer quick setup times and are ideal for smaller print runs or on-demand printing.

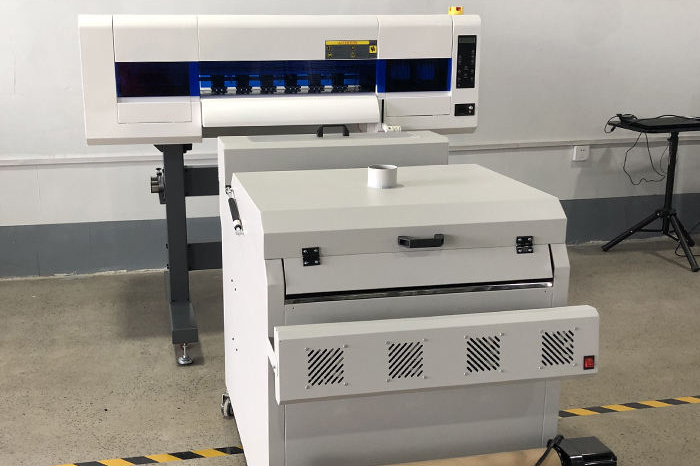

3. Hybrid DTF Printer:

Hybrid DTF printers combine the capabilities of both roll-to-roll and sheet-fed printers. These printers offer the flexibility to print on both rolls of film and individual sheets, providing small businesses with the best of both worlds. Hybrid DTF printers are suitable for businesses that have varying production needs, allowing them to switch between roll-to-roll and sheet-fed modes based on their specific requirements. They offer versatility and can handle both high-volume production and smaller print runs.

4. Resolution and Print Quality:

When choosing a DTF printer, it's important to consider the resolution and print quality it offers. Higher resolution printers produce more detailed and sharper prints, resulting in better quality output. Look for printers that offer high-resolution capabilities, ensuring that your custom apparel maintains a professional and visually appealing look.

5. Ink Configuration:

DTF printers use different ink configurations, including CMYK (Cyan, Magenta, Yellow, Black) and additional ink channels like white and/or clear. Consider the type of designs you plan to print and choose a printer with the appropriate ink configuration. For example, if you frequently print on dark-colored fabrics, a printer with white ink capability will allow you to create vibrant and opaque prints.

6. Software Compatibility and Support:

Ensure that the DTF printer you choose is compatible with the design software you use or plan to use. Check for software compatibility and availability of printer drivers or plugins. Additionally, consider the level of technical support provided by the printer manufacturer or supplier. Having reliable technical support can greatly assist you in resolving any issues or concerns that may arise during the printing process.

Choosing the right DTF printer is essential for small businesses seeking to venture into custom apparel production. Understanding the differences between roll-to-roll, sheet-fed, and hybrid DTF printers, considering resolution and print quality, ink configuration, and ensuring software compatibility and support are crucial factors to consider. By selecting the appropriate DTF printer, small businesses can optimize their production capabilities, deliver high-quality custom apparel, and meet the demands of their customers efficiently.

kenteer has launched DTF printers for customers. If you have any needs, you can contact us for a quote.