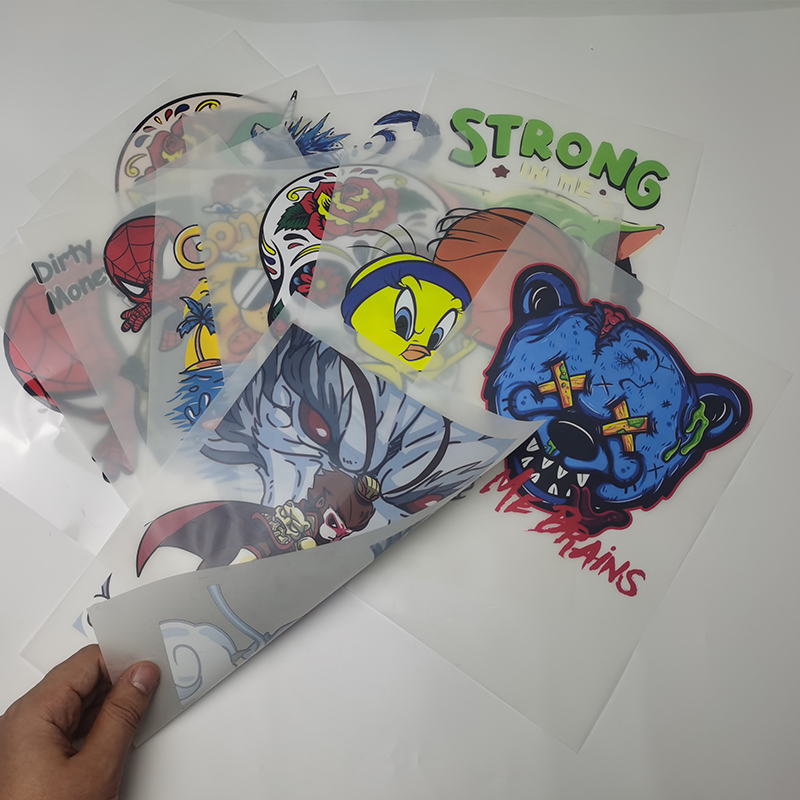

Direct-to-Film Printing combines the convenience of digital printing with the versatility of screen printing. DTF (Direct-to-Film) film sheets have taken the printing industry by storm, offering a groundbreaking method for transferring designs onto various surfaces.

Understanding DTF Film Sheets

DTF film sheets are a remarkable innovation that combines the benefits of digital printing and screen printing. These sheets are made up of a flexible polymer material that can be printed using an inkjet printer. Unlike traditional screen printing, DTF film sheets eliminate the need for screens, allowing for direct printing of designs onto the film. The printed design is then transferred onto the desired substrate using a combination of heat and pressure, resulting in a vibrant and durable print.

The Application Process

The application process of DTF film sheets involves a series of simple yet precise steps. First, the design is created digitally using specialized software and then printed onto the DTF film sheet using an inkjet printer equipped with DTF ink. The printed film is then placed on top of the substrate, such as a t-shirt or a tote bag, with the printed side facing down. Heat and pressure are applied using a heat press machine, causing the ink to sublimate and adhere to the surface of the substrate. After cooling and removing the film, the result is a high-quality, long-lasting print.

Versatility and Advantages

One of the most remarkable aspects of DTF film sheets is their versatility. They can be used on a wide range of materials, including cotton, polyester, leather, wood, ceramics, and more. This flexibility makes DTF printing suitable for various industries, including fashion, interior design, promotional products, and custom merchandise.

Moreover, DTF film sheets offer several advantages over traditional printing methods. Firstly, they enable the reproduction of intricate and highly detailed designs with remarkable precision. The digital nature of the printing process allows for unlimited color possibilities, gradients, and photographic prints.

Secondly, DTF printing offers exceptional durability and longevity. The ink penetrates the fibers of the substrate, resulting in a print that withstands regular wear and multiple washes without fading or cracking. This durability makes DTF printing ideal for creating high-quality apparel and other consumer goods.

Furthermore, DTF film sheets provide a cost-effective solution for small to medium-sized print runs. With no need for screens or color separations, setup costs are significantly reduced, making it accessible to individuals and small businesses.

Limitations and Considerations

While DTF film sheets offer numerous advantages, it is important to consider their limitations. The printing process requires an inkjet printer capable of handling DTF ink

which may require an additional investment. Additionally, achieving optimal results may require some experimentation with printer settings, heat press temperature, and pressure.

It is also worth noting that DTF printing is most suitable for white or light-colored substrates. The ink's opacity may be compromised when printed on dark materials, requiring a pre-treatment with a white base layer for optimal color vibrancy.

DTF film sheets have revolutionized the printing industry, bridging the gap between digital printing and screen printing. Their versatility, precision, and durability make them a game-changer for artists, designers, and manufacturers. With the ability to print on various materials and reproduce intricate designs, DTF printing opens up a world of creative possibilities.