The KTM-A05 A3 UV Flatbed Printer stands as a testament to technological advancement, revolutionizing the realm of printing with its exceptional capabilities. This article delves into the intricate workings of this remarkable machine, unraveling the mechanisms that enable it to produce stunning prints on a vast array of materials.

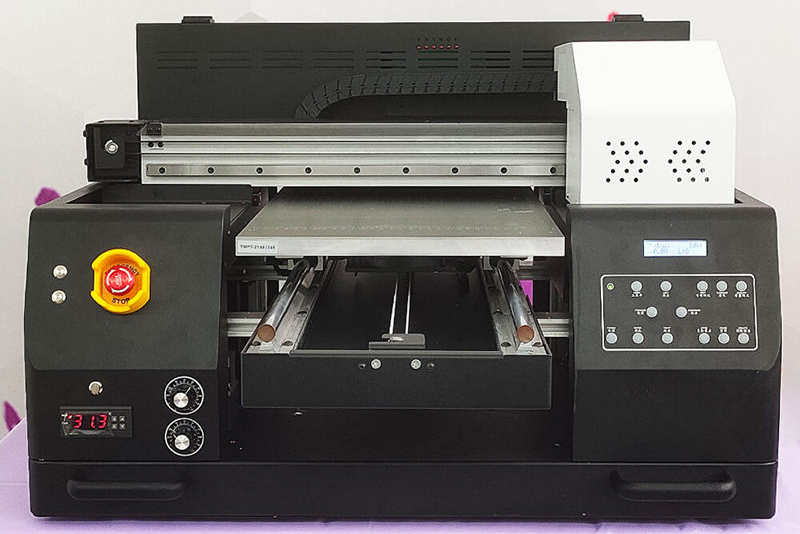

Control Panel: The Command Center

The KTM-A05's control panel serves as the command center, orchestrating the printer's operations with precision. From initiating print jobs to adjusting settings, the control panel empowers users to seamlessly control the printing process.

Limit Sensor: Ensuring Precise Material Height

The astute limit sensor plays a crucial role in ensuring accurate material height. By automatically detecting the material's surface level, the limit sensor guarantees that the print head maintains an optimal distance, preventing misprints and ensuring consistent print quality.

Railway: A Durable Foundation for Smooth Operation

The KTM-A05 boasts a high-quality steel guide rail, forming a robust railway that underpins the print head's movement. This durable structure ensures smooth, precise carriage movement, minimizing vibrations and contributing to exceptional print quality.

Missing Ink Alarm Light: A Guardian Against Ink Depletion

The vigilant missing ink alarm light serves as a sentinel, alerting users when ink levels dwindle. This proactive notification system prevents printing interruptions and ensures a seamless printing experience.

Platform Lift Button & Emergency Stop Button: Safety and Control at Your Fingertips

The platform lift button empowers users to effortlessly raise and lower the printing platform, facilitating easy material loading and unloading. Conversely, the emergency stop button serves as a safety mechanism, immediately halting printing operations in case of unforeseen circumstances.

Platform Suction Button, Temperature Button & Powder Adjustment Button: Fine-Tuning for Optimal Results

The platform suction button activates a powerful vacuum system, firmly securing the printing material in place during the printing process. The temperature button allows users to regulate the printing environment, ensuring optimal ink adhesion and print quality. Finally, the powder adjustment button enables fine-tuning of the powder coating, enhancing print adhesion and color vibrancy.

Unveiling the Printing Process

The KTM-A05's printing process is a symphony of mechanical precision and technological ingenuity. Here's a step-by-step breakdown of the intricate workings:

1. Material Preparation: The printing material is carefully loaded onto the platform and secured using the platform suction button.

2. Material Height Detection: The astute limit sensor automatically detects the material's height, ensuring optimal print head positioning.

3. Inkjet Printing: The two Epson XP600 print heads meticulously deposit UV ink onto the material, creating a digital image with remarkable precision.

4. UV Curing: Powerful UV lamps bathe the printed surface, instantly curing the ink and ensuring its permanence.

5. Powder Coating (Optional): For enhanced print adhesion and color vibrancy, an optional powder coating step is applied. The powder adjustment button allows for precise control of the powder application.

6. Printing Completion: Once the printing process is complete, the platform is lowered, allowing users to effortlessly remove the finished product.

The KTM-A05 A3 UV Flatbed Printer stands as a testament to technological innovation, offering a versatile and powerful printing solution for a wide range of applications. Its robust construction, intelligent features, and precise printing mechanism ensure exceptional print quality and consistent performance. Whether you're a seasoned professional or a budding entrepreneur, the KTM-A05 empowers you to unleash your creativity and produce stunning prints that will captivate your audience.

If you have product purchasing needs, you can contact us.