Amidst the ever-evolving landscape of printing technologies, Direct-to-Film printing has emerged as a game-changer, revolutionizing the way custom designs are transferred onto various substrates. At the heart of this innovative process lies the DTF Oven, a remarkable device that plays a pivotal role in curing and fusing the printed designs onto the film, ensuring exceptional durability and vibrant colors.

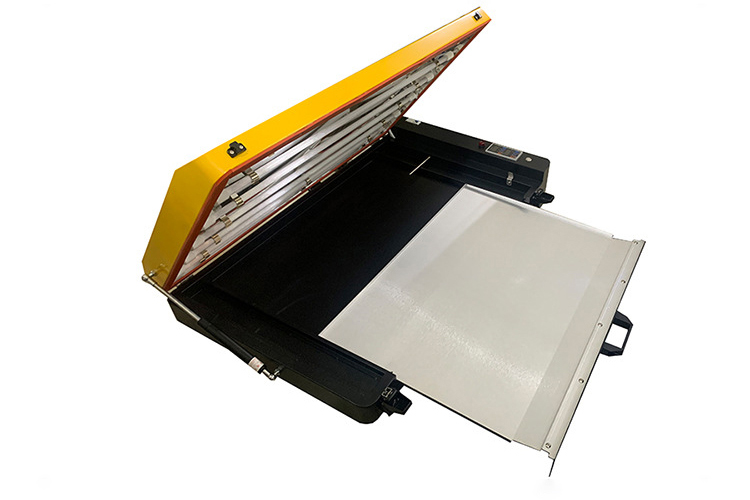

Delving into the technical intricacies of the DTF Oven, we uncover a symphony of meticulously engineered components and features that orchestrate a seamless and efficient printing experience.

1. Precise Temperature and Time Control

The DTF Oven's advanced temperature control system maintains consistent and precise heating conditions throughout the curing process. This ensures that the ink and powder are perfectly cured, resulting in superior adhesion and resistance to fading or cracking. Moreover, the adjustable timer allows for fine-tuning the curing time based on the specific requirements of the design and substrate.

2. Uniform Heat Distribution

The oven's design incorporates a sophisticated air circulation system that ensures uniform heat distribution across the entire heating chamber. This eliminates the risk of uneven curing, preventing blemishes or inconsistencies in the printed design. The result is a consistently high-quality output with sharp details and vibrant colors.

3. Energy Efficiency and Safety

The DTF Oven is meticulously engineered to minimize energy consumption while maintaining optimal performance. Its insulation properties effectively retain heat within the chamber, reducing energy wastage and lowering operating costs. Additionally, multiple safety features, such as overheating protection and automatic shutdown mechanisms, ensure safe and reliable operation, minimizing the risk of accidents.

4. User-Friendly Interface

The DTF Oven features an intuitive and user-friendly control panel that simplifies operation and minimizes the learning curve. Clear displays and easy-to-understand controls allow users to effortlessly adjust temperature, time, and other settings, maximizing productivity and minimizing errors.

5. Compact and Versatile Design

Despite its robust capabilities, the DTF Oven boasts a compact design that seamlessly integrates into various printing environments. Its space-saving footprint and lightweight construction make it easy to position and transport, accommodating diverse production needs and maximizing workspace efficiency.

the DTF Oven stands as a technological marvel, seamlessly blending precision, efficiency, and user-friendliness. Its advanced features and meticulous design empower users to achieve exceptional results with minimal effort, making it an indispensable tool for modern DTF printing setups.

Kenteer supplies DTF Oven. Customers in need are welcome to contact us.