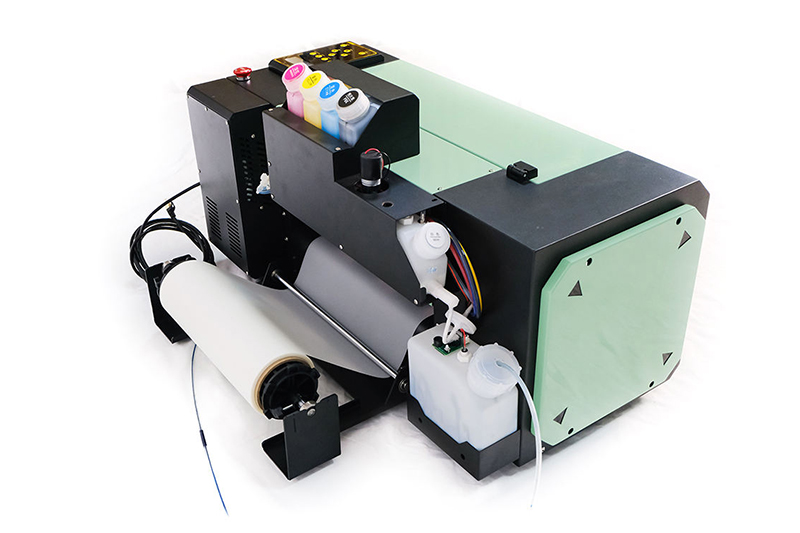

The printing industry is continually evolving, with new technologies emerging to meet the growing demand for highquality and versatile printing solutions. One of the most significant advancements in recent years is the Direct to Film (DTF) printing technology, which has revolutionized the way we print on various materials. Leading this innovation is the KTM33200 DTF Printer by Kenteer. This stateoftheart printer is designed to deliver exceptional performance and versatility, making it a gamechanger for businesses and professionals in the printing industry. In this article, we will delve into the technical features of the KTM33200 DTF Printer, highlighting its capabilities and advantages.

Technical Specifications of the KTM33200 DTF Printer

The KTM33200 DTF Printer is packed with advanced features that set it apart from other printers in the market. Below is a detailed overview of its technical specifications:

Print Head Type: The KTM33200 is equipped with dual EPSONI1600 print heads. These print heads are renowned for their precision and reliability, ensuring highquality prints every time.

Printing Width: The printer boasts a maximum printing width of ≤330mm, allowing for a broad range of applications, from small labels to larger designs.

Print Configuration: The KTM33200 supports a color configuration of Color+White (CMYK+WWww), enabling vibrant and detailed prints on dark and light fabrics alike.

Compatible Media: This DTF Printer is compatible with PET DTF Film, a popular choice for its excellent ink absorption and durability.

Transfer Media: The versatility of the KTM33200 is evident in its ability to print on various materials, including nylon, synthetic fiber, cotton fabric, leather, swimsuit, diving suit, PVC, EVA, and more. This makes it ideal for producing custom apparel, accessories, and promotional items.

Printing Speed: The printer offers multiple printing speeds to suit different production needs. It can achieve speeds of 6Pass2.5m²/H, 8Pass1.5m²/H, 8Pass3m²/H, and 12Pass2m²/H, providing flexibility for both highvolume and detailed printing jobs.

Ink Type: The KTM33200 uses pigment ink, which is known for its vibrant colors, durability, and resistance to fading, making it perfect for highquality, longlasting prints.

Printing Precision: With a printing precision of 1440/2160/2880 DPI, the KTM33200 ensures sharp and detailed images, suitable for intricate designs and highresolution graphics.

RIP Software: The printer utilizes RIN RIP software, a powerful tool that enhances the printing process by optimizing image quality and color management.

Operating System Compatibility: The KTM33200 is compatible with both Windows 7 and Windows 10 operating systems, ensuring broad accessibility and ease of use.

Heating and Drying Function: To ensure the best print quality, the printer features front and rear arcplate heating, platform suction, and LED lighting. These functions help to quickly dry the prints and maintain consistent quality.

Platform Suction: The adjustable suction size on the platform ensures that the media stays in place during printing, preventing smudges and ensuring precise prints.

Printing Interface: The KTM33200 is equipped with a gigabit ethernet port, enabling fast and reliable data transfer for efficient printing operations.

Temperature and Humidity Requirements: The printer operates optimally within a temperature range of 1530°C and a humidity range of 3565%, ensuring stable performance in various environments.

Electrical Parameters: The printer requires a power supply of 50Hz/60Hz, 220V, 15A, and 0.5KW, making it energyefficient and suitable for most standard electrical setups.

Dimensions and Weight: The compact design of the KTM33200, with dimensions of 795330442mm and a net weight of 40kg, makes it easy to fit into any workspace. The packaging dimensions are 850490649mm with a gross weight of 60kg, ensuring safe and secure transport.

If you have product purchasing needs, you can contact us.