While DTF powder shaker machines are generally reliable, occasional issues may occur during their operation. Here are some common troubleshooting techniques to address potential problems with DTF powder shaker machines:

1. Uneven Powder Distribution:

Issue: The machine may distribute the adhesive powder unevenly, resulting in inconsistent coverage on the printed design.

Troubleshooting:

- Ensure that the machine is placed on a stable surface to prevent shaking or vibrations that may affect powder distribution.

- Check for any obstructions or debris that may be blocking the powder distribution mechanism. Clean the machine if necessary.

- Adjust the shaking or vibration settings to achieve a more even and consistent powder distribution.

- Use a proper powder-to-ink ratio to ensure that the adhesive powder is evenly applied. Experiment with different ratios to find the optimal one for your specific printing needs.

2. Powder Clumping:

Issue: The adhesive powder may clump together, causing blockages or uneven application.

Troubleshooting:

- Store the adhesive powder in a cool and dry environment to prevent moisture absorption, which can lead to clumping.

- Check the powder consistency regularly and break up any clumps before loading them into the machine.

- Ensure that the machine's powder container or hopper is clean and free from any residual powder or debris that may contribute to clumping.

- Adjust the shaking or vibration settings to prevent excessive force that can cause the powder to clump together.

3. Powder Waste:

Issue: The machine may generate excessive powder waste, leading to unnecessary costs and environmental impact.

Troubleshooting:

- Optimize the powder-to-ink ratio to minimize waste while still ensuring adequate adhesive coverage.

- Adjust the shaking or vibration settings to reduce excessive powder dispersion.

- Consider using a powder reclamation system or collecting excess powder for reuse in subsequent prints.

- Regularly clean and maintain the machine to prevent powder buildup and blockages that contribute to wastage.

4. Machine Jamming or Malfunction:

Issue: The machine may experience jamming or malfunctioning, resulting in interrupted or inconsistent operation.

Troubleshooting:

- Check for any mechanical obstructions or loose parts that may be causing the jam. Clear any blockages and tighten loose components as necessary.

- Ensure that the machine is properly calibrated and aligned to prevent misfeeds or jams.

- Regularly clean and lubricate the machine's moving parts to ensure smooth operation.

- If the issue persists, consult the machine's user manual or contact technical support for further guidance or professional assistance.

Regular maintenance, proper calibration, and adherence to manufacturer guidelines are essential in preventing and addressing issues with DTF powder shaker machines. It's important to familiarize yourself with the specific troubleshooting procedures outlined in the machine's user manual. Additionally, documenting any recurring issues and their resolutions can help streamline future troubleshooting efforts and improve overall machine performance.

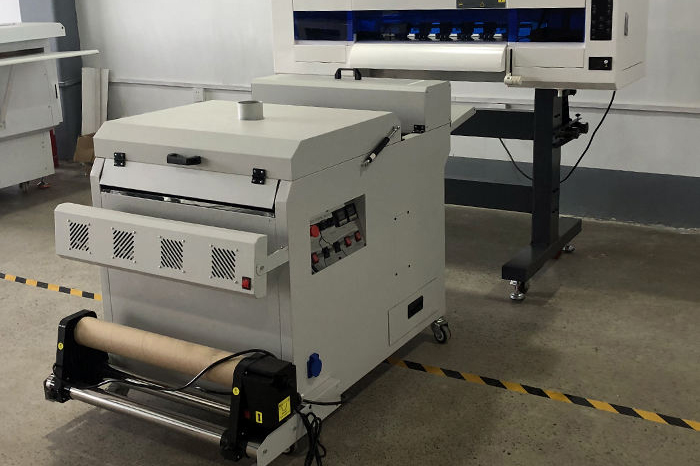

kenteer has launched DTF powder shaker machines for customers . If you have any needs, you can contact us for a quote.