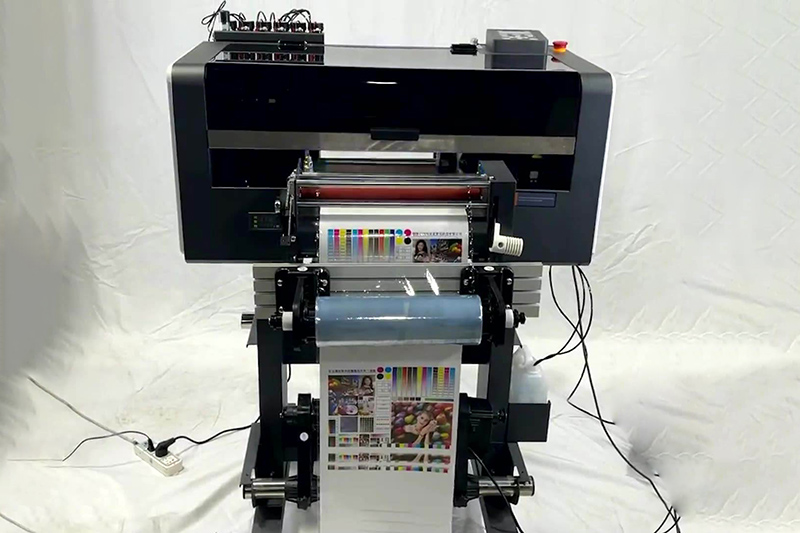

The Kenteer KTM-A12 UV printer represents a significant advancement in digital printing technology, offering businesses a versatile and efficient solution for a wide range of applications. With its impressive specifications and compact design, the KTM-A12 is poised to disrupt the market and empower businesses to explore new creative avenues. This article will delve into the market applications and technological trends surrounding the KTM-A12 and UV printers in general, highlighting the key features that make this printer a valuable asset for various industries.

Market Applications:

The KTM-A12 UV printer, with its 300mm printing width and high-resolution output, opens doors to a diverse range of applications. Its ability to print directly onto various substrates, including wood, acrylic, metal, glass, and ceramics, makes it ideal for personalized customization, promotional products, and industrial printing.

-

Signage and Display: The vibrant colors and sharp details achievable with the KTM-A12 UV printer make it perfect for creating eye-catching signage, exhibition graphics, and point-of-sale displays. The UV-cured ink ensures long-lasting prints that are resistant to fading and weathering, making them suitable for both indoor and outdoor use.

-

Promotional Products: The KTM-A12 empowers businesses to personalize a wide range of promotional items, including phone cases, pens, mugs, and USB drives. Its ability to print on irregularly shaped objects adds a new dimension to product customization, offering unique branding opportunities.

-

Packaging and Labels: High-quality, customized packaging plays a crucial role in product branding and consumer appeal. The KTM-A12 UV printer allows for the creation of visually appealing labels and packaging designs directly onto various materials, streamlining the production process and reducing turnaround times.

-

Industrial Printing: The durability and versatility of UV printing make it suitable for various industrial applications, including marking and coding, product identification, and control panel graphics. The KTM-A12’s ability to print on different materials makes it a valuable tool for manufacturers in diverse industries.

-

Interior Decoration: From customized wall panels and furniture to decorative tiles and artwork, the KTM-A12 UV printer offers interior designers and architects a powerful tool for creating unique and personalized spaces. The ability to print directly onto various substrates opens up a world of creative possibilities for interior decoration.

Technological Trends in UV Printing:

The UV printer market is constantly evolving, driven by advancements in ink technology, print head design, and automation. The KTM-A12 embodies several key trends shaping the future of UV printing:

-

Increased Print Speed and Efficiency: The KTM-A12's dual XP600 printheads and variable print speeds allow for efficient production, catering to both high-volume and high-quality printing needs. This trend towards faster and more efficient UV printers is crucial for businesses seeking to maximize productivity and reduce turnaround times.

-

Enhanced Ink Versatility: UV ink technology is constantly evolving, with new formulations offering improved adhesion, color vibrancy, and durability. The KTM-A12's compatibility with CMYK, white, and varnish inks expands creative possibilities and allows for a wider range of printing applications. Developments in specialty inks, such as metallic and fluorescent inks, are further expanding the capabilities of UV printers.

-

Improved Automation and Workflow Integration: The integration of advanced software and automation features is streamlining the UV printing process. The KTM-A12's user-friendly RIIN software simplifies print job management and enhances workflow efficiency. Trends towards automated substrate handling and inline finishing options are further improving the productivity of UV printing systems.

-

Focus on Sustainability: The UV printing industry is increasingly focused on environmentally friendly practices. UV-cured inks are inherently more sustainable than traditional solvent-based inks, as they do not emit volatile organic compounds (VOCs). The development of bio-based UV inks and recyclable substrates further enhances the sustainability of UV printing.

-

3D Printing Capabilities: While the KTM-A12 focuses on 2D printing, the UV printing technology is increasingly being utilized in 3D printing applications. UV-curable resins allow for the creation of intricate and durable 3D objects with a high level of detail. This convergence of 2D and 3D printing technologies is opening up new possibilities for product development and customization.

The KTM-A12 UV printer represents a compelling option for businesses seeking a versatile and efficient digital printing solution. Its ability to print directly onto a wide range of substrates, combined with its high-resolution output and efficient operation, makes it a valuable asset for various industries, from signage and promotional products to packaging and industrial printing. As UV printer technology continues to evolve, with a focus on increased speed, enhanced ink versatility, and improved automation, the KTM-A12 is well-positioned to meet the evolving needs of the market and empower businesses to explore new creative horizons. The continued development and refinement of UV Printer technology promises to further expand the applications and capabilities of this dynamic printing method.