The manufacturing process of Kenteer's glitter film rolls involves several steps and technologies to achieve the desired glittery effect. Here is an overview of the typical process and technologies involved:

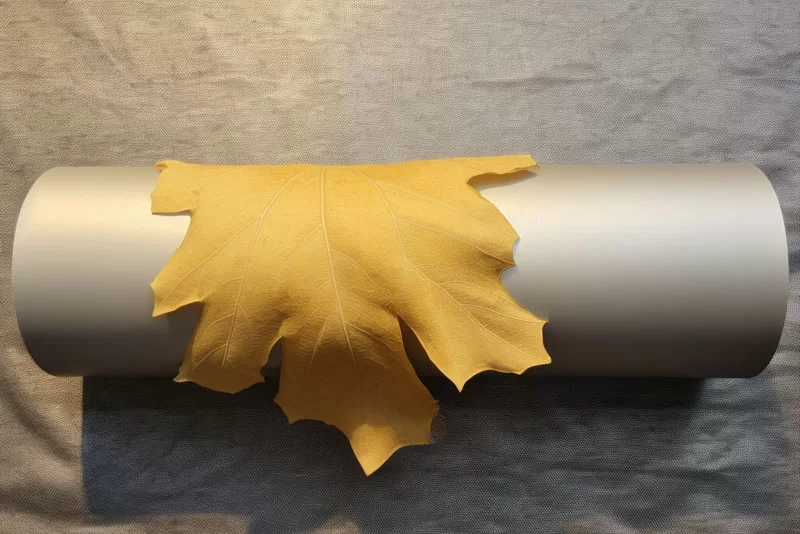

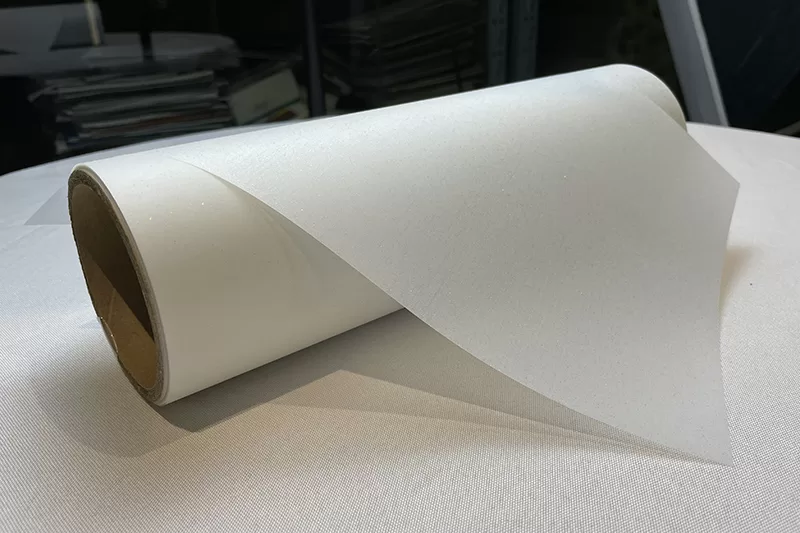

1. Base Film Production: The process begins with the production of a base film. This film serves as the foundation onto which the glitter particles will be applied. The base film can be made of various materials such as polyester (PET), polyvinyl chloride (PVC), or other suitable polymers.

2. Coating: The base film is coated with a layer of adhesive or primer to ensure proper adhesion of the glitter particles. This coating helps the glitter particles adhere firmly to the film and prevents them from flaking off during application or use.

3. Glitter Application: Glitter particles are applied to the adhesive-coated film. This can be done using various methods, including:

- Hot Stamping: In this method, a heated metal plate or roller is used to transfer the glitter particles onto the adhesive-coated film. The heat activates the adhesive, ensuring the glitter particles adhere to the film.

- Screen Printing: Glitter particles can also be applied through screen printing, where a fine mesh screen with a stencil of the desired design or pattern is used. The glitter particles are pushed through the screen onto the adhesive-coated film, creating the desired glittery design.

- Digital Printing: With advancements in digital printing technology, it is now possible to directly print glitter particles onto the adhesive-coated film. Specialized printers with glitter ink or toner are used to achieve this effect.

4. Protective Coating: Once the glitter particles are applied, a protective coating is often added to enhance durability and prevent the glitter from shedding or fading. This coating can be a clear varnish or a layer of protective film that seals the glitter particles and provides a smooth finish.

5. Slitting and Rewinding: The glitter-coated film is then slit into rolls of the desired width. Slitting machines are used to cut the film into narrower strips, which are then rewound onto individual rolls.

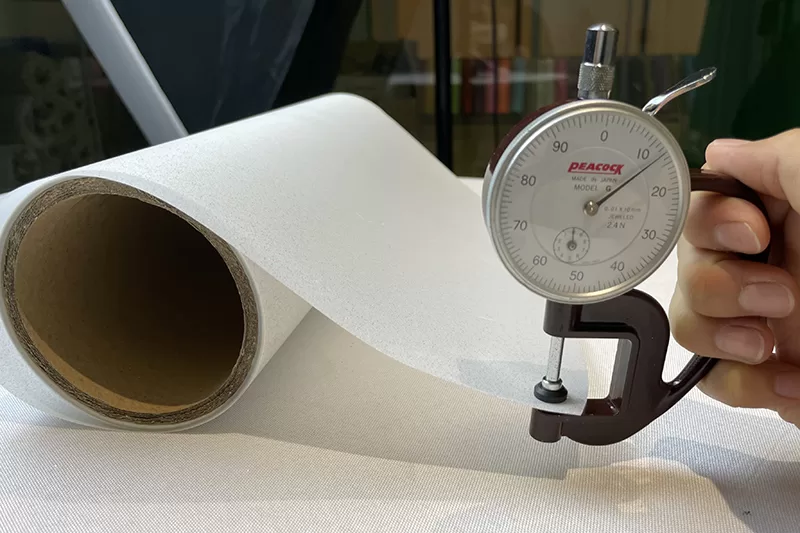

6. Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the desired glitter effect, adhesion, and durability. This may involve visual inspection, testing for colorfastness and adhesion strength, and other quality checks.

The technologies used in the manufacturing process of glitter film rolls include coating machines, hot stamping equipment, screen printing machinery, digital printers, and slitting and rewinding machines. These technologies enable precise application of glitter particles, efficient production, and consistent quality.

It's worth noting that the specific manufacturing process and technologies can vary depending on the manufacturer and the desired characteristics of the Kenteer's glitter film rolls. Advanced manufacturing techniques and technologies continue to evolve, providing new possibilities for creating glitter film rolls with improved durability, enhanced visual effects, and eco-friendly features.