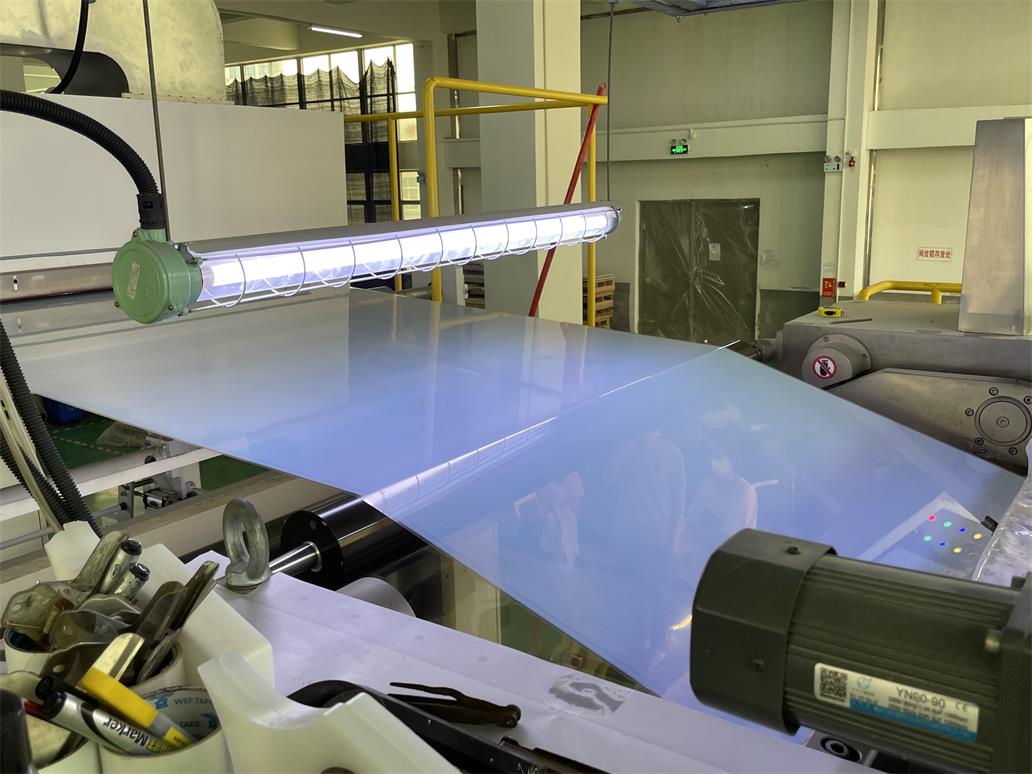

DTF printing offers a wide range of compatible substrates, making it a versatile printing method with numerous applications. Here are some of the substrates that are compatible with DTF printing:

1. Fabrics: DTF printing can be applied to various fabrics, including cotton, polyester, blends, and more. It allows for vibrant and detailed designs on garments such as t-shirts, hoodies, hats, and sportswear. DTF prints adhere well to fabric fibers, resulting in durable and long-lasting prints.

2. Leather: DTF printing is compatible with leather materials, enabling customization and personalization of leather products such as wallets, belts, shoes, and bags. It offers the ability to print intricate designs, logos, or personalized messages on leather surfaces.

3. Denim: DTF printing can be used on denim fabrics, adding unique designs and patterns to jeans, jackets, or other denim apparel items. It allows for detailed prints and vibrant colors on denim surfaces, enhancing the overall look and appeal of the garments.

4. Synthetic Materials: DTF printing is also compatible with various synthetic materials, including nylon, spandex, and polypropylene. This compatibility allows for diverse applications in the production of swimwear, activewear, and other synthetic textile products.

5. Accessories: DTF printing can be applied to a wide range of accessories, including bags, backpacks, hats, scarves, and more. It offers the opportunity to print logos, graphics, or custom designs on these accessories, enhancing their visual appeal and customization options.

6. Home Decor: DTF printing enables customization of home decor items such as cushions, pillowcases, curtains, tablecloths, and more. It allows for the transfer of vibrant and detailed designs onto these textile surfaces, adding a personalized touch to interior decor.

7. Promotional Products: DTF printing can be used to create customized promotional products like pens, keychains, lanyards, or bottle openers. It enables the printing of logos, branding elements, or custom designs on these promotional items, making them visually appealing and effective marketing tools.

8. Upholstery: DTF printing is compatible with upholstery fabrics, offering the opportunity to print unique designs on furniture, car seats, or other upholstered surfaces. It allows for customization and personalization of these items, creating one-of-a-kind pieces.

The compatibility of DTF printing with a wide range of substrates makes it a versatile printing method suitable for various industries and applications. Its ability to deliver vibrant and durable prints on different materials opens up possibilities for customization, personalization, and creative design in the world of textile printing.

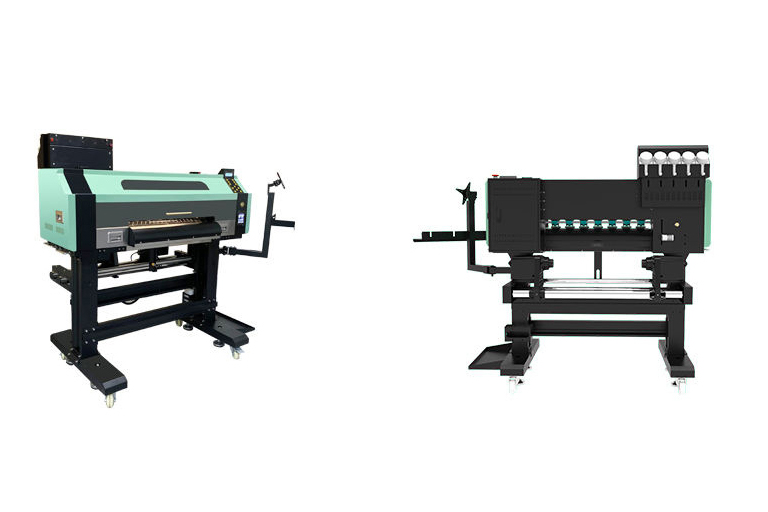

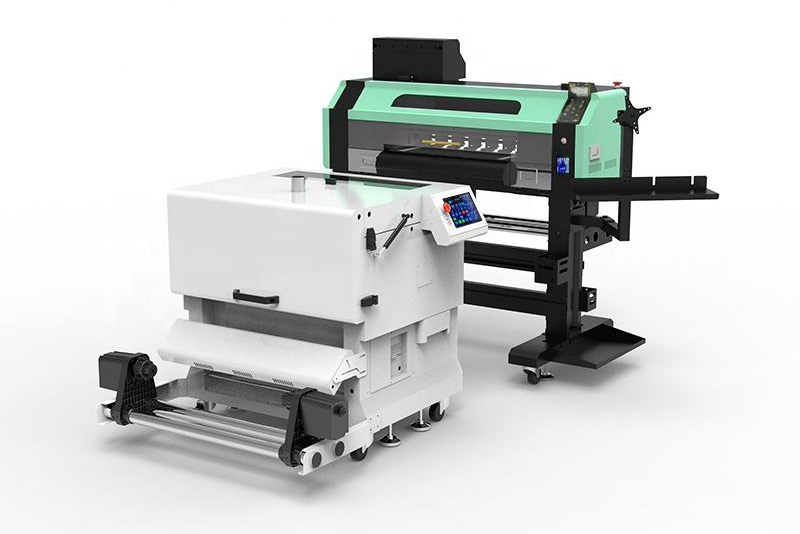

kenteer has launched DTF printers for customers . If you have any needs, you can contact us for a quote.