Proper storage and handling are crucial in transfer tape manufacturing to ensure the quality, performance, and longevity of the product. Here are the key reasons why proper storage and handling are important in transfer tape manufacturing:

1. Preservation of Adhesive Properties: Transfer tape relies on its adhesive properties to bond effectively to various surfaces. Proper storage and handling help preserve these adhesive properties. Exposure to extreme temperatures, humidity, or contaminants can degrade the adhesive, leading to reduced bonding strength and performance. By storing transfer tape in controlled environments and handling it with care, manufacturers can maintain the adhesive properties and ensure consistent performance.

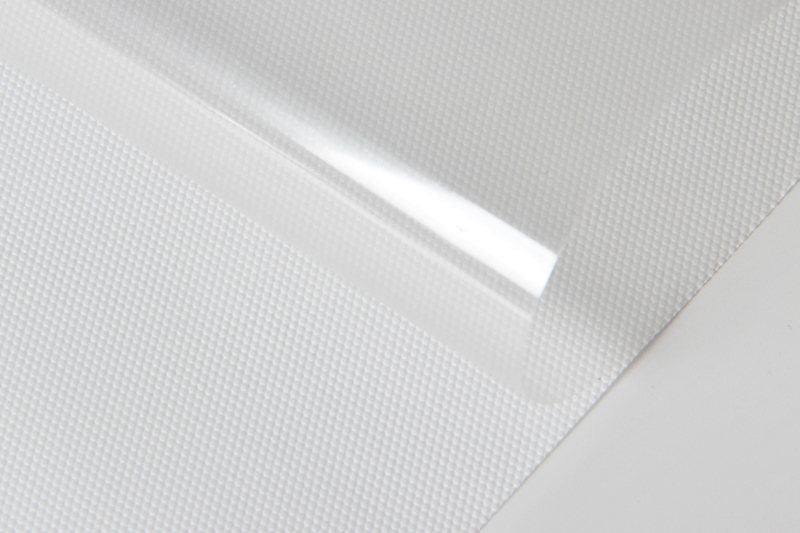

2. Prevention of Contamination: Transfer tape is susceptible to contamination, which can affect its adhesive properties and overall performance. Proper storage and handling minimize the risk of contamination from dust, dirt, oils, or other substances that can compromise the adhesive. Keeping transfer tape in clean and sealed packaging, and handling it with clean gloves or tools, reduces the chances of contamination during production and storage.

3. Protection against Physical Damage: Transfer tape is sensitive to physical damage, such as creasing, tearing, or bending. Proper storage and handling practices help protect the transfer tape from such damage. Storing the tape in a flat position, avoiding excessive pressure or weight, and using appropriate handling techniques minimize the risk of physical damage. This ensures that the transfer tape remains intact and usable throughout its shelf life.

4. Prevention of Moisture Absorption: Moisture can negatively impact the adhesive properties of transfer tape. It can cause the adhesive to soften, resulting in reduced bonding strength and performance. Proper storage in a dry environment and sealing the packaging effectively prevent moisture absorption. Additionally, handling transfer tape with dry hands and avoiding exposure to high humidity conditions during production help maintain the integrity of the adhesive.

5. Shelf Life Extension: Transfer tape has a limited shelf life, which can be extended through proper storage and handling. Storing the tape in a cool, dry place away from direct sunlight and extreme temperature fluctuations helps preserve its performance over time. Following recommended storage and handling guidelines provided by the manufacturer ensures that the transfer tape remains viable for a longer period.

6. Consistent Product Quality: Proper storage and handling practices contribute to consistent product quality in transfer tape manufacturing. By maintaining the adhesive properties, preventing contamination and damage, and minimizing moisture absorption, manufacturers can ensure that each batch of transfer tape meets the required specifications and performance standards. Consistent product quality enhances customer satisfaction and reduces the risk of product failures or recalls.

Overall, proper storage and handling practices are essential in transfer tape manufacturing to preserve adhesive properties, prevent contamination and physical damage, extend shelf life, and maintain consistent product quality. Adhering to recommended guidelines and implementing appropriate storage and handling protocols during production and storage processes are critical for maximizing the performance and usability of transfer tape.

Kenteer is producing transfer tape , please contact us if you need cooperation.