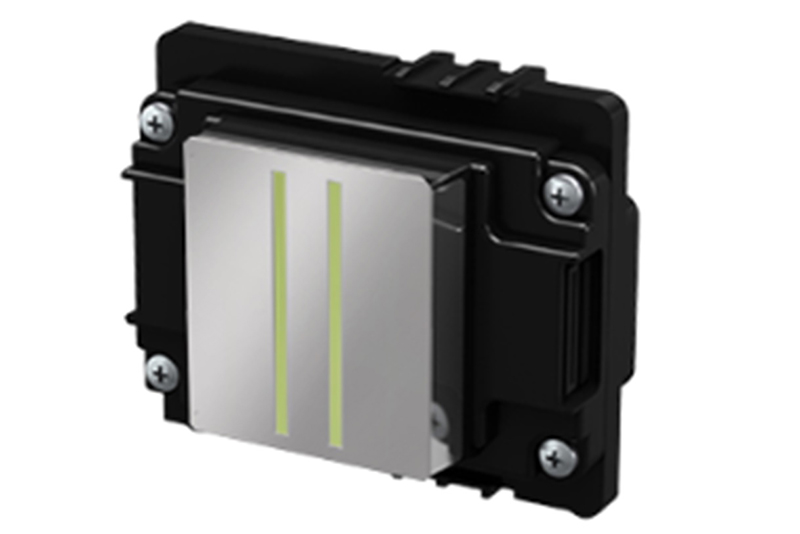

The I1600-A1 printhead is a cutting-edge component of inkjet printers, offering exceptional performance for producing high-quality prints. This article delves into the intricate working principles of this advanced printhead, shedding light on its design, operation, and key features.

Introduction to Inkjet Printing

Inkjet printing technology is based on the precise ejection of tiny ink droplets onto paper or other substrates. The I1600-A1 printhead is the heart of this process, responsible for controlling the ink flow and accurately directing droplets to create the desired patterns.

Design and Architecture

The I1600-A1 printhead features an innovative design, comprising 1600 nozzles arranged in four rows. These nozzles are spaced 1/300 inch apart within each row, ensuring precise ink placement and sharp image quality. The printhead has a width of 33.8 mm, enabling it to cover a wide print area efficiently.

Piezoelectric Actuation

The printhead employs piezoelectric actuation technology, where electrical signals trigger the movement of tiny piezoelectric crystals. These crystals vibrate rapidly, creating pressure within the ink chambers and propelling ink droplets out of the nozzles.

Ink Control and Droplet Formation

The I1600-A1 printhead utilizes sophisticated ink control mechanisms to ensure consistent and accurate ink flow. The piezoelectric crystals generate controlled pressure pulses, which force ink droplets of specific volumes to be ejected from the nozzles. The printhead supports multiple droplet sizes, allowing for varying gray levels and improved image detail.

Resolution and Print Quality

The I1600-A1 printhead boasts impressive resolution capabilities, achieving 300 npi (nozzles per inch) with one ink column and 600 npi with two ink columns. This high resolution enables the production of sharp and detailed prints, ideal for both text and graphics.

Ink Compatibility

The I1600-A1 printhead is designed with optimized materials and adhesives to ensure compatibility with a wide range of inks. This versatility allows for seamless integration into different printing systems and the use of various ink formulations.

Durability and Reliability

The I1600-A1 printhead is engineered for exceptional durability and reliability. It has been rigorously tested to withstand billions of piezoelectric actuations without compromising performance. Additionally, the printhead exhibits excellent resistance to pressure cleaning, ensuring longevity and consistent operation.

The I1600-A1 printhead is a technological marvel that embodies the latest advancements in inkjet printing. Its precise ink control, high resolution, and robust design make it an essential component for producing superior-quality prints. As the industry continues to evolve, printheads like the I1600-A1 will undoubtedly play a pivotal role in shaping the future of printing technology.

The above is the printer nozzle information provided by Kenteer. If you need to purchase printer equipment, you can contact us.