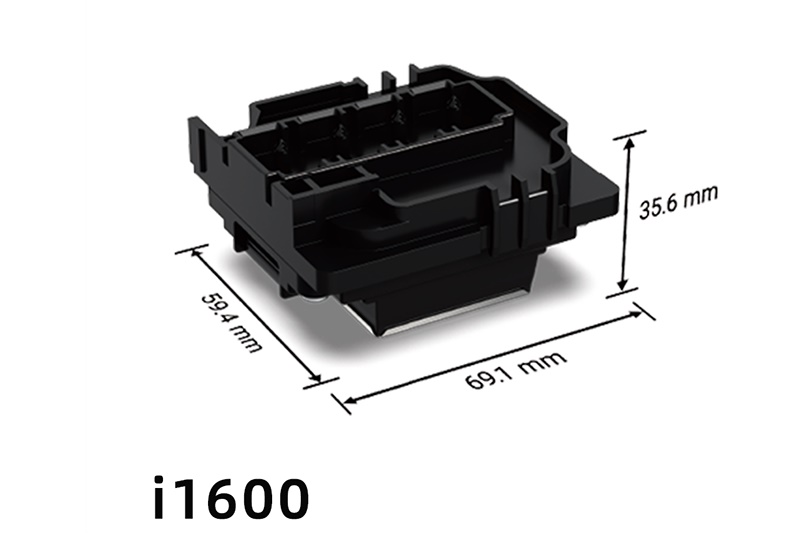

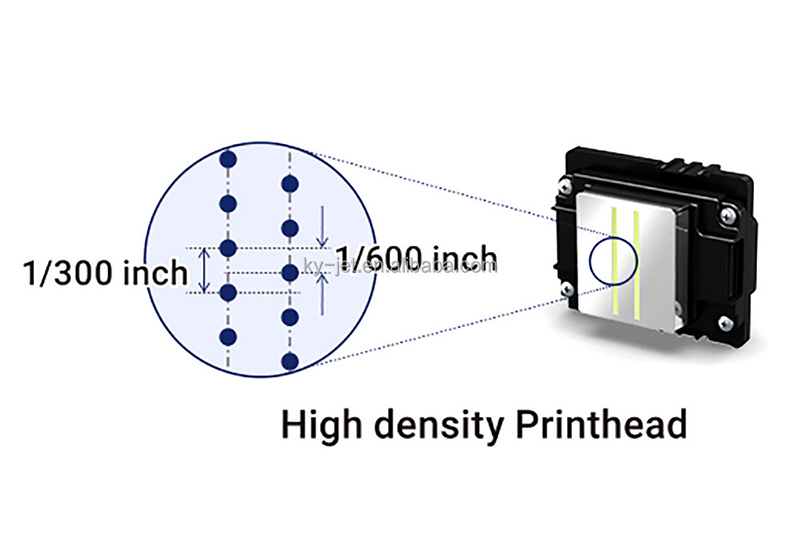

The I1600-A1 printhead is a 1-inch entry-level inkjet printhead with 4 colors, designed for use in a variety of industrial printing applications. It features AQ inks, a compact design, and high-resolution printing capabilities. The printhead's parameters include 1600 nozzles, 1/300 inch nozzle pitch, 4 nozzle columns, and a maximum of 4 supported ink colors. It offers resolutions of 300npi/1 column and 600npi/2 columns, with an effective printing width of 33.8 mm.

Choosing the right supplier for the I1600-A1 printhead is crucial to ensure the quality and reliability of your printing operations. Here are some essential factors to consider when selecting a supplier:

1. Reputation and Experience:

Choose a supplier with a proven track record and years of experience in the industry. Look for suppliers who have established relationships with reputable manufacturers and a history of providing high-quality products.

2. Product Availability and Lead Time:

Ensure the supplier has readily available stock of the I1600-A1 printhead to meet your production needs. Inquire about the supplier's lead times to avoid delays in your operations.

3. Technical Expertise and Support:

Select a supplier that provides technical expertise and support for the I1600-A1 printhead. They should be able to assist you with installation, maintenance, and troubleshooting issues.

4. Competitive Pricing and Value for Money:

Compare prices from different suppliers to ensure you are getting the best value for your investment. Consider the overall package, including the printhead's performance, reliability, and the supplier's support services.

5. After-Sales Support and Warranty:

Look for a supplier that offers comprehensive after-sales support and a warranty for the I1600-A1 printhead. This will provide you with peace of mind and protection in case of any defects or issues.

6. Customer Service and Communication:

Choose a supplier with excellent customer service and communication. They should be responsive to inquiries, provide clear and timely updates, and address your concerns promptly.

7. Compliance and Standards:

Ensure the supplier complies with industry standards and regulations for the I1600-A1 printhead. This includes certifications such as RoHS and REACH, which demonstrate the printhead's conformity to environmental and safety requirements.

8. Certifications and Accreditations:

Consider suppliers who have obtained industry certifications or accreditations. These certifications provide independent verification of the supplier's quality management systems and product standards.

9. Quality Control and Traceability:

Select a supplier that has a robust quality control system in place to ensure the consistency and reliability of the I1600-A1 printhead. Inquire about their traceability measures to track the printheads from manufacturing to delivery.

10. Environmental Responsibility:

Choose a supplier that demonstrates a commitment to environmental responsibility. Look for suppliers who engage in sustainable practices and offer environmentally friendly alternatives, such as recycled or recyclable packaging.

Selecting the right supplier for the I1600-A1 printhead is essential for ensuring the success of your printing operations. By carefully evaluating the factors discussed above, you can make an informed decision and partner with a supplier that provides high-quality products, excellent support, and value for your investment.

The above is the printer nozzle information provided by Kenteer. If you need to purchase printer equipment, you can contact us.