The KTM-60604 is a state-of-the-art, 60cm four-head DTF (Direct-to-Film) printer designed to empower businesses with unparalleled printing capabilities for vibrant, durable designs on a vast range of materials. This high-end machine boasts an array of impressive features and functionalities, making it the ultimate solution for businesses seeking exceptional print quality, versatility, and efficiency.

Unmatched Print Quality and Precision

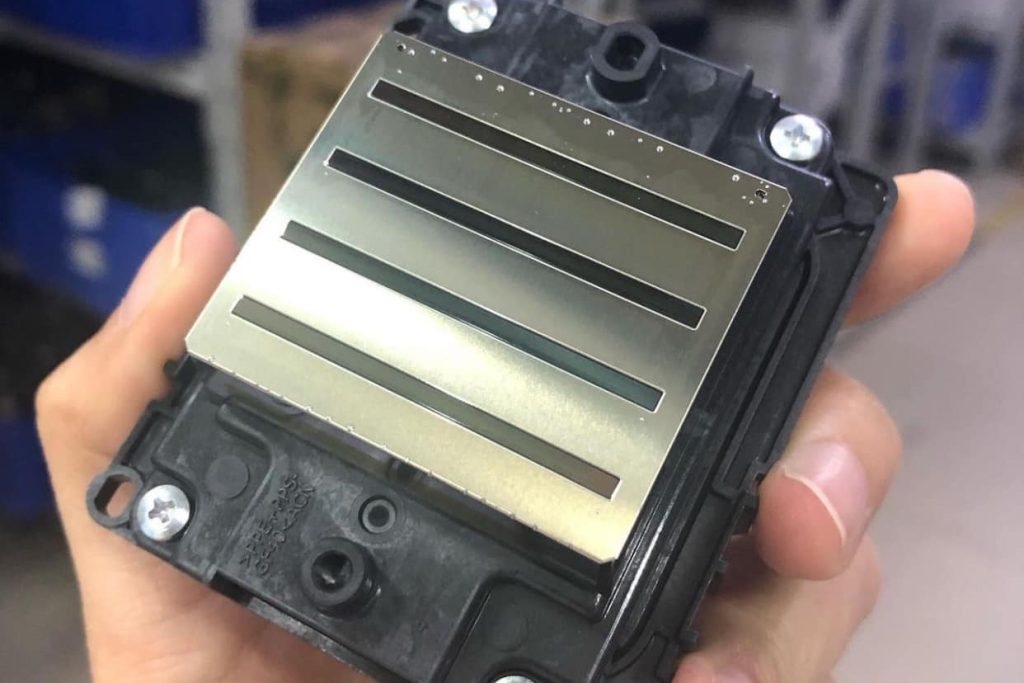

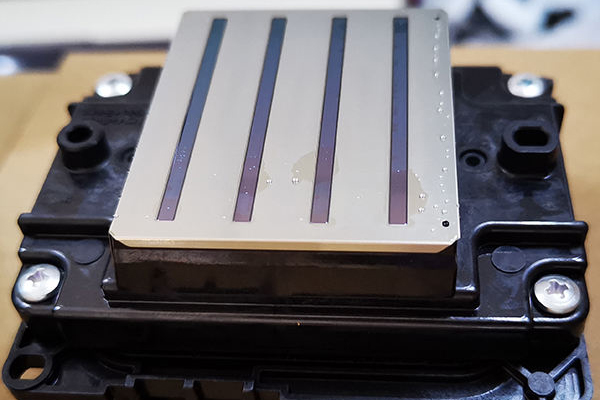

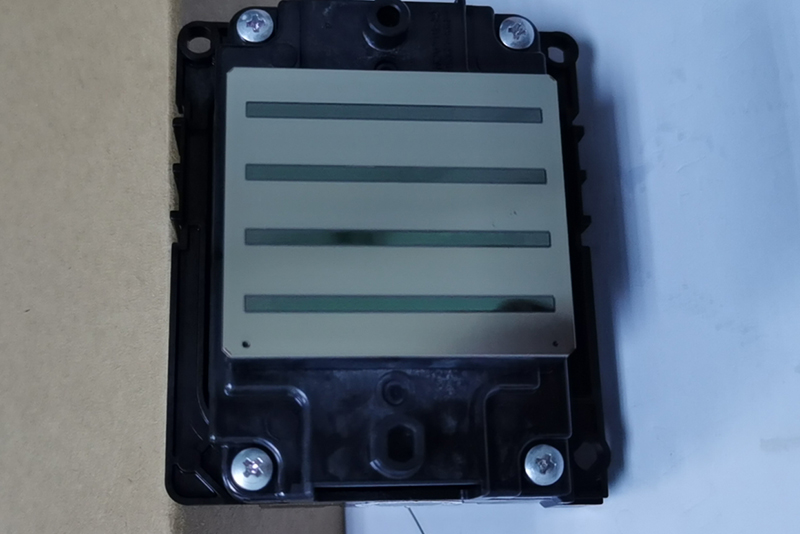

At the heart of the KTM-60604 lies its advanced print head configuration. Equipped with four i3200 print heads, this printer delivers stunning print resolutions of 1440, 2160, and 2880 dpi, ensuring crisp details and vibrant colors in every print. The CMYK-2+WWWW-2 configuration allows for exceptional color accuracy and vibrancy, while the dedicated white ink channels ensure opaque and bright white prints on both light and dark fabrics.

Uncompromising Versatility

The KTM-60604 offers unparalleled versatility in terms of printable materials. It seamlessly handles a wide range of media, including nylon, polyester, cotton, leather, swimwear, diving suits, PVC, and EVA. This opens up a world of possibilities for businesses to expand their product offerings and cater to diverse customer needs.

Enhanced Productivity and Efficiency

This DTF printer is engineered for optimal productivity and efficiency. With impressive print speeds of 16m/H (6Pass) and 25m/H (4Pass), businesses can fulfill high-volume orders quickly and efficiently. Additionally, the printer incorporates several features that streamline workflow and minimize downtime, including:

- Automatic pre-heating and post-heating of platen Ensures optimal ink adhesion and drying for consistent print quality.

- Vacuum suction platform Provides stable media handling for accurate printing.

- LED lighting Illuminates the printing area for easy monitoring.

- Ink level monitoring and white ink circulation Prevents unexpected ink shortages and ensures consistent white ink density.

- Printhead anti-collision system Protects print heads from damage and minimizes downtime.

- One-click automatic cleaning Simplifies maintenance and ensures optimal print head performance.

- Integrated lifting ink stack Saves space and facilitates easy ink cartridge replacement.

- Automatic paper feeding and lifting lever Streamlines media loading and reduces manual intervention.

- Paper shortage and waste ink alarm Prevents printing errors and ensures timely maintenance.

- Automatic media tension control Ensures smooth and consistent media feeding.

Intuitive Operation and User-Friendly Design

The KTM-60604 is designed with user-friendliness in mind. It comes equipped with a dedicated computer and monitor stand, providing a space-saving and efficient workspace. The multi-function control panel allows for easy operation and monitoring of printing processes. Additionally, the printer utilizes a user-friendly RIP software (PP/蒙泰Maintop) and is compatible with Windows 7 and Windows 10 operating systems.

Investing in Excellence

The KTM-60604 DTF printer is a powerful and versatile solution for businesses seeking to elevate their printing capabilities and expand their product offerings. Its exceptional print quality, impressive speed, and user-friendly design make it an ideal choice for businesses of all sizes. By investing in the KTM-60604, businesses can unlock new levels of creativity, efficiency, and profitability.

If you have product purchasing needs, you can contact us