The KTM-1908, an 8-head high-speed sublimation printer, enters a dynamic market experiencing rapid growth and evolution. Direct-to-Film (DTF) printing technology has revolutionized garment decoration, offering a versatile and efficient alternative to traditional methods like screen printing and direct-to-garment (DTG) printing. Understanding the current trends within this market is crucial for comprehending the potential impact and success of the KTM-1908.

Trend 1: Increasing Demand for Customization and Personalization

Consumers today crave unique and personalized products, driving the demand for on-demand printing solutions. DTF printing caters perfectly to this need, allowing for the creation of custom designs on various fabrics, including cotton, polyester, blends, and even dark-colored garments. The KTM-1908, with its ability to print intricate designs and vibrant colors, is well-positioned to capitalize on this trend. Its compatibility with the braid and pyrography industry further expands its potential for personalized customization.

Trend 2: Growing Popularity of DTF Printing in the Apparel Industry

DTF printing offers several advantages over traditional methods, including:

Versatility: DTF prints adhere to a wide range of fabrics, eliminating limitations associated with fabric type or color.

Durability: DTF prints are known for their excellent wash and wear resistance, ensuring long-lasting designs.

Cost-Effectiveness: DTF printing eliminates the need for pre-treatment or expensive equipment, making it a cost-effective solution for small businesses and startups.

Ease of Use: The DTF process is relatively simple, requiring minimal training and expertise.

These advantages have led to the increasing adoption of DTF printing in the apparel industry, particularly for small-batch production, custom apparel, and promotional items. The KTM-1908, with its user-friendly features and efficient operation, caters to this growing market segment.

Trend 3: Technological Advancements in DTF printers

The DTF printing technology is continuously evolving, with manufacturers focusing on improving print quality, speed, and reliability. The KTM-1908 exemplifies this trend with its advanced features, such as:

High-Speed Printing: The 8-head configuration allows for faster production speeds, meeting the demands of high-volume printing.

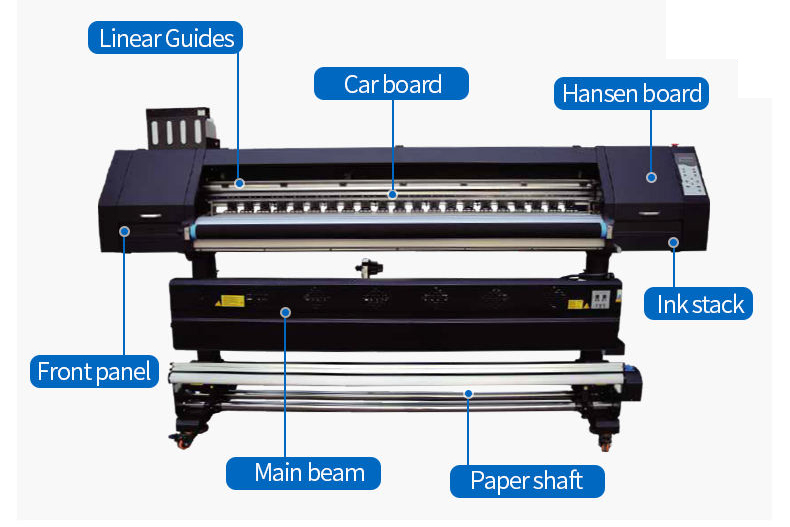

All-Aluminum Ink Stack: This innovative design enhances the printer's durability and reliability, minimizing downtime and maintenance costs.

Auto Constant Temperature Drying System: This system ensures uniform heating and optimal ink absorption, resulting in high-quality prints with vibrant colors and sharp details.

Intelligent Reminder Functions: Features like ink and paper shortage alarms streamline the printing process and prevent interruptions.

These advancements contribute to the overall efficiency and user experience, making the KTM-1908 a competitive option in the market.

Trend 4: Expansion into New Markets and Applications

DTF printing is expanding beyond the apparel industry, finding applications in home décor, accessories, and promotional products. The ability to print on various materials opens up new possibilities for customization and personalization. The KTM-1908, with its versatility and advanced features, is well-suited to explore these emerging markets.

Trend 5: Sustainability Concerns and Eco-Friendly Solutions

As environmental awareness grows, the printing industry faces increasing pressure to adopt sustainable practices. DTF printing offers some advantages in this regard, such as reduced water usage compared to traditional methods. However, the use of plastic films and potential waste generation remain concerns. Manufacturers like KTM are expected to focus on developing eco-friendly solutions, such as recyclable films and water-based inks, to address these concerns and cater to environmentally conscious consumers.

Challenges and Opportunities

Despite the positive trends, the DTF printing market also faces challenges. Competition is intensifying, with numerous manufacturers offering a wide range of printers at varying price points. Additionally, the technology is still evolving, and some users may experience challenges with color consistency, adhesion, and durability.

However, these challenges also present opportunities for innovation and improvement. Manufacturers who can address these issues and offer reliable, high-quality printers with advanced features will be well-positioned for success in this growing market.

The DTF printing market is experiencing significant growth, driven by the increasing demand for customization, the technology's versatility and cost-effectiveness, and continuous advancements in printer capabilities. The KTM-1908, with its advanced features and focus on user experience, is well-positioned to capitalize on these trends and contribute to the ongoing evolution of the DTF printing industry. As the market continues to expand and evolve, manufacturers who can adapt to changing consumer preferences and address emerging challenges will be at the forefront of this exciting technology.

If you have product purchasing needs, you can contact us.