The digital age has ushered in a new era of personalization and customization. Consumers are no longer satisfied with mass-produced products; they crave unique items that reflect their individuality. This shift in consumer behavior has spurred innovation in the printing industry, with the rise of technologies that enable small-batch, on-demand printing.

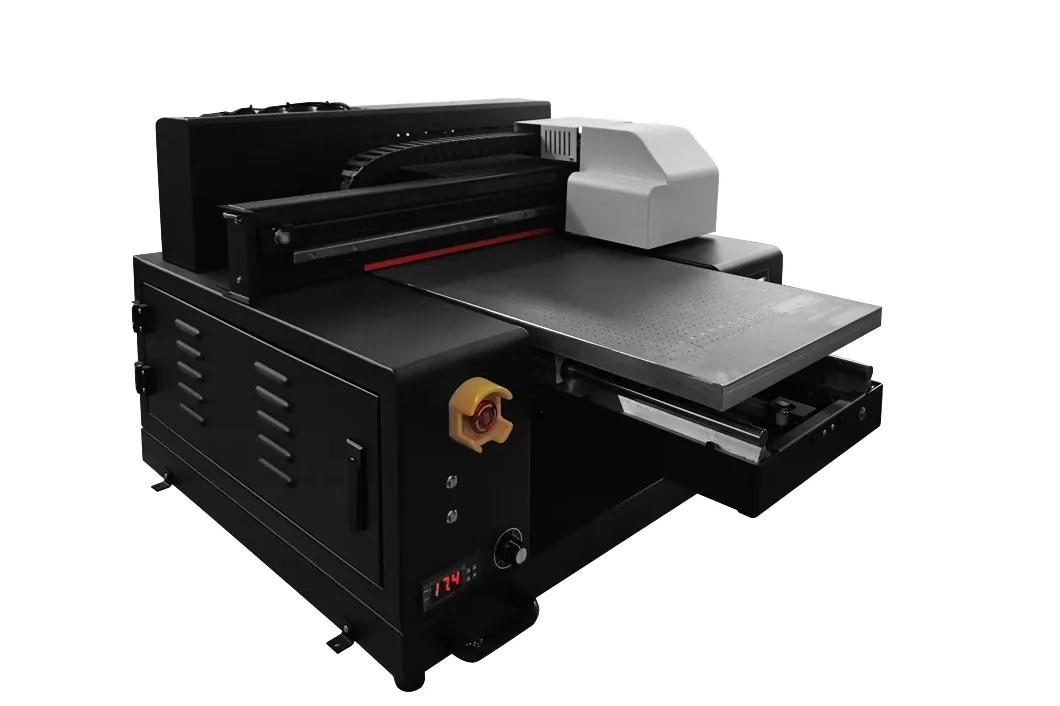

One such innovation is the Kenteer KTM-A05 A3 UV Flatbed Printer . This compact and versatile machine allows users to directly print high-quality, full-color images onto a wide variety of materials. This article delves into the technical aspects of the KTM-A05, exploring its features and capabilities, and how it contributes to the growing trend of small-scale customization.

Unpacking the KTM-A05: Features and Functionality

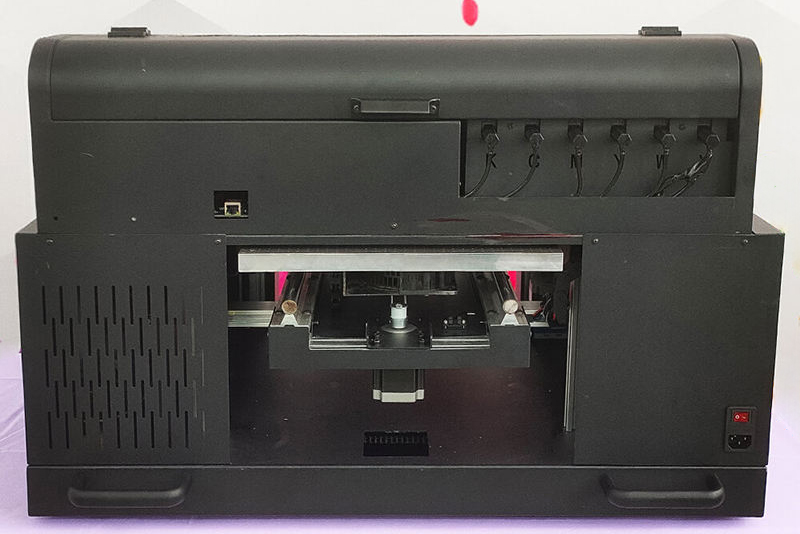

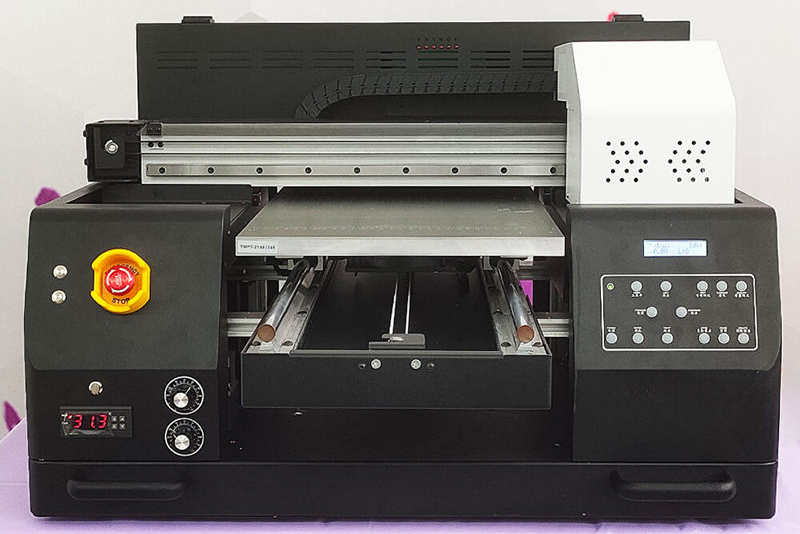

The KTM-A05 boasts a user-friendly design with a control panel for managing printing operations. Automatic material height detection is ensured by limit sensors, eliminating the need for manual adjustments. The printer utilizes high-quality steel guide rails for smooth and precise movement of the print head, guaranteeing long-lasting performance.

For seamless operation, the KTM-A05 incorporates an ink alarm system that notifies users when ink levels are low. Additionally, the platform lift button allows for easy loading and unloading of materials, while the emergency stop button prioritizes safety during operation. Further enhancing user control, the platform suction button secures materials in place, while the temperature button and powder adjustment button provide precise control over the printing environment.

Powering Up Personalization: The Technical Specifications

At the heart of the KTM-A05 lies its dual Epson XP600 print heads. These renowned print heads deliver exceptional print quality with a resolution of 1440 x 1440 DPI, ensuring sharp and vibrant images. The printer boasts a maximum printing height of 12cm, accommodating a variety of material thicknesses.

The KTM-A0 operates at an impressive speed, completing a full-color A3 print within 10 minutes. This efficient printing speed makes it ideal for small-scale production runs and on-demand printing needs.

Unleashing Creativity: Material Versatility

The KTM-A05 shines in its ability to print on a diverse range of materials. From phone cases and acrylic keychains to pens, helmets, and even ceramic tiles, wood, metal, and glass, the printer caters to a wide range of customization projects. This versatility empowers users to personalize everyday objects, create unique promotional items, or produce short-run product samples.

Ink and Power: Technical Considerations

The KTM-A05 utilizes UV ink, a special type of ink that cures instantly under ultraviolet light. This technology allows for printing on a broader range of materials compared to traditional solvent-based inks. The printer employs a CMYK WW + 6 varnish ink configuration, offering a full spectrum of colors and the option to add a protective glossy finish to prints.

The printer operates on a standard voltage range of 110-220V with a frequency of 50-60Hz, making it compatible with most power outlets globally. Its power consumption is rated at 300W, ensuring efficient operation without excessive energy demands.

Compact Design, Big Potential: The Future of Small-Scale Customization

With its compact footprint (80 x 75 x 50 cm), the KTM-A05 is ideal for small businesses, workshops, and even home-based studios. Its user-friendly interface and intuitive controls make it accessible to both seasoned professionals and printing enthusiasts.

The growing popularity of the KTM-A05 reflects the increasing demand for on-demand customization. This printer empowers individuals and small businesses to bring their creative visions to life, personalizing everyday objects and creating unique products. As technology continues to evolve, we can expect even more advancements in small-scale printing solutions, further democratizing the power of personalization and fostering a future where self-expression reigns supreme.

If you have product purchasing needs, you can contact us.