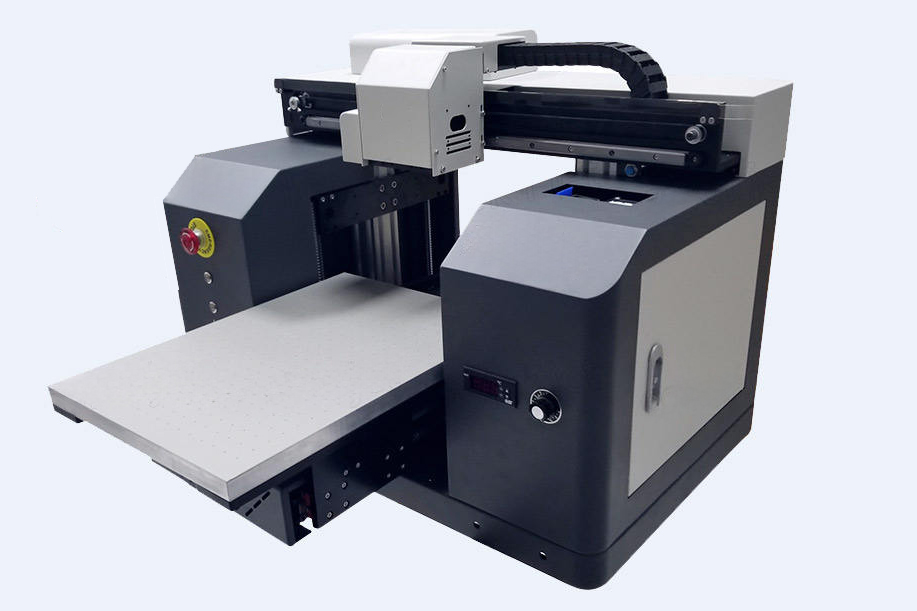

The KTM-A06 DTF UV Flatbed Printer is a revolutionary printing machine that utilizes Direct Transfer Film (DTF) technology to deliver exceptional printing quality on a wide range of materials. This innovative printer is equipped with cutting-edge features that make it ideal for various applications, including signage, phone cases, promotional items, and much more.

Unparalleled Printing Performance

At the heart of the KTM-A06 lies the F1080 or I3200 printhead, capable of producing stunning resolutions of up to 720 x 4320 dpi. This ensures that your prints are incredibly sharp, detailed, and vibrant, exceeding the expectations of even the most discerning customers.

The printer boasts a remarkable printing speed, reaching up to 3㎡/h in production mode, 1.5㎡/h in precision mode, and 1㎡/h in high precision mode. This efficiency allows you to meet tight deadlines and handle large print volumes without compromising quality.

Versatility and Flexibility

The KTM-A06 DTF UV FLATBED PRINTER is incredibly versatile, capable of printing on a diverse range of materials, including glass, acrylic board, wood, board, metal, and leather. This versatility makes it a valuable asset for businesses that cater to a wide variety of clients and applications.

With its adjustable print height of 3mm to 240mm, the printer can accommodate objects of various sizes and shapes, ensuring that you can print on virtually any item that fits within the printing area.

Advanced Ink System

The KTM-A06 utilizes a 6/7 color ink system, including glue, color, white, varnish, KCMY glue, white, and varnish. This advanced ink system provides exceptional color gamut, allowing you to create prints with vivid colors, sharp details, and a glossy finish.

The printer's ink delivery system ensures consistent ink flow and prevents clogging, minimizing downtime and maximizing productivity.

User-friendly Operation

The KTM-A06 DTF UV Flatbed Printer is designed with ease of use in mind. It features a user-friendly interface that makes it simple to operate, even for those with limited printing experience.

The printer comes with powerful RIP software that allows you to easily manage your print jobs, adjust settings, and achieve optimal results.

Durability and Reliability

Built with high-quality components and materials, the KTM-A06 DTF UV Flatbed Printer is designed to withstand the rigors of everyday use. Its durable construction ensures long-lasting performance and minimizes the need for maintenance.

The printer is backed by comprehensive warranty coverage, providing peace of mind and ensuring that your investment is protected.

The KTM-A06 DTF UV Flatbed Printer represents a significant advancement in printing technology. Its exceptional printing quality, versatility, advanced ink system, user-friendly operation, and durability make it an ideal choice for businesses that demand the best. With its ability to produce stunning prints on a wide range of materials, the KTM-A06 is sure to set a new standard for printing excellence.

If you have product purchasing needs, you can contact us.