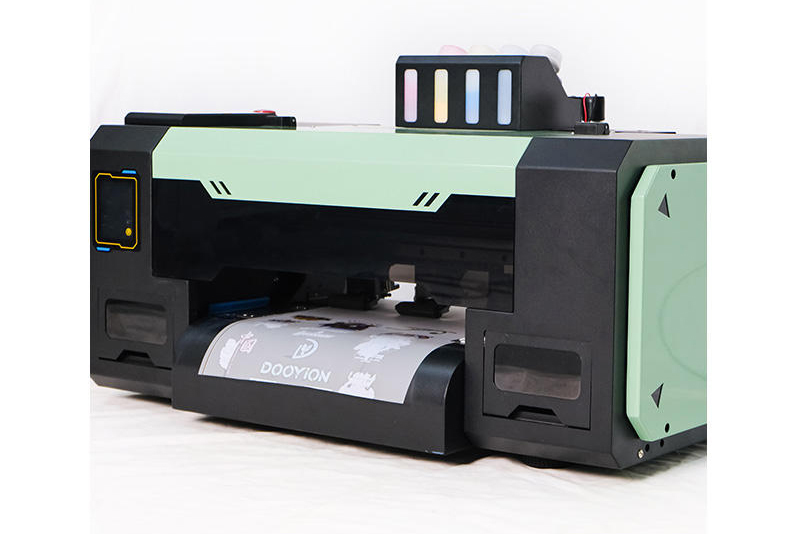

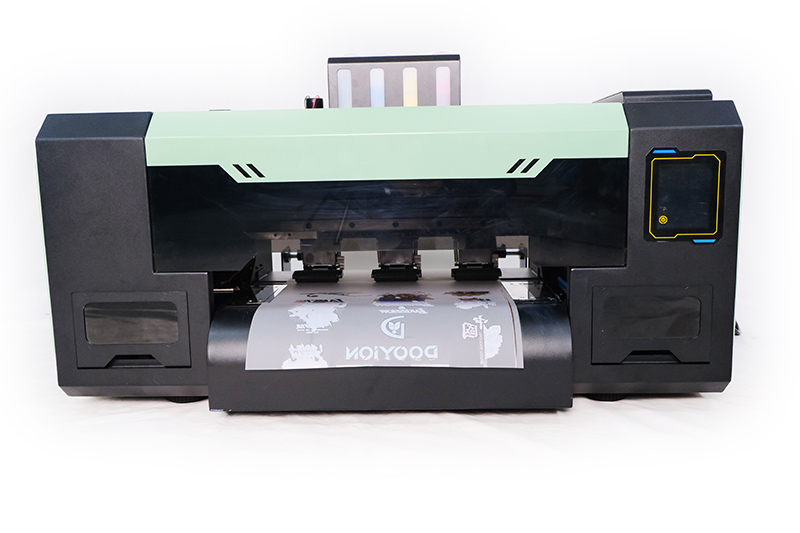

The Kenteer KTM-33200 DTF Printer is a cutting-edge digital textile printing solution designed to revolutionize the way you approach custom apparel and fabric decoration. This versatile machine offers a wide range of features and capabilities that make it a popular choice for both professional print shops and DIY enthusiasts. In this comprehensive buyer's guide, we will delve into the key specifications, benefits, and considerations when purchasing the KTM-33200.

Key Features and Specifications

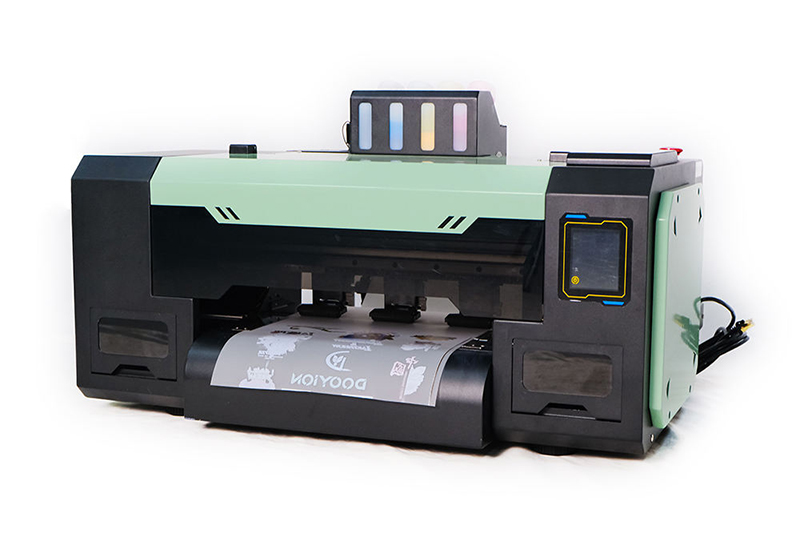

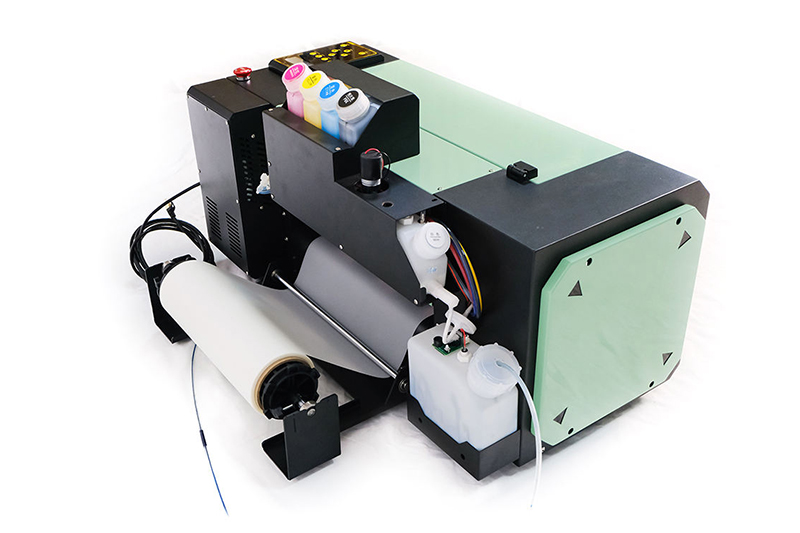

The KTM-33200 is equipped with a dual Epson I1600 print head, enabling high-speed, high-quality printing. With a printing width of up to 330mm, it can accommodate a variety of fabric sizes. Some of the standout features include:

Versatile Media Compatibility: The printer can handle a wide array of materials, including nylon, synthetic fibers, cotton, leather, swimwear, diving suits, PVC, EVA, and more.

High-Precision Printing: With a resolution of up to 2880 DPI, the KTM-33200 delivers exceptional print quality and fine detail.

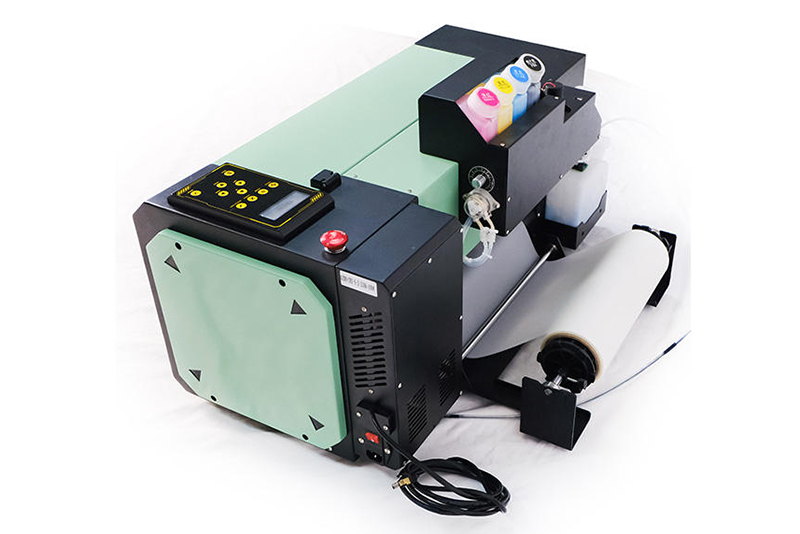

Efficient Heating and Drying: The integrated heating and drying system ensures that the printed ink cures quickly and adheres firmly to the fabric.

User-Friendly Interface: The printer is controlled by a user-friendly interface, making it easy to operate for users of all skill levels.

RIP Software: The included RIN RIP software provides powerful color management tools and pre-flight checks to optimize print output.

Benefits of DTF Printing with the KTM-33200

Versatility: DTF printing offers unmatched versatility, allowing you to print on a wide range of materials and fabrics.

High-Quality Prints: The KTM-33200 delivers vibrant, long-lasting prints with exceptional detail.

No Screen Setup Required: Unlike traditional screen printing, DTF printing eliminates the need for screen creation, saving time and reducing costs.

Small Batch Production: DTF printing is ideal for small batch production and custom orders.

Eco-Friendly: DTF printing is a more environmentally friendly process compared to traditional textile printing methods.

Considerations When Purchasing a KTM-33200 DTF Printer

Print Volume: Evaluate your expected print volume to determine the appropriate printer model and configuration.

Material Compatibility: Consider the specific materials you plan to print on to ensure compatibility with the printer.

Ink Costs: Factor in the cost of DTF inks and other consumables when budgeting for the printer.

Maintenance: DTF printers require regular maintenance to ensure optimal performance and print quality.

Training: If you are new to DTF printing, consider investing in training to learn best practices and troubleshooting techniques.

The Kenteer KTM-33200 DTF Printer is a powerful and versatile tool for creating custom textiles. Its ability to produce high-quality prints on a wide range of materials makes it a valuable asset for businesses and individuals alike. By carefully considering the factors discussed in this guide, you can make an informed decision about whether the KTM-33200 is the right DTF printer for your needs.

If you have product purchasing needs, you can contact us.