The world of garment printing is undergoing a revolution, and at the forefront of this change is Direct-to-Film (DTF) printing technology. Offering unparalleled versatility, vibrant colors, and impressive durability, DTF printing has become a game-changer for businesses and individuals alike. Leading the charge in this exciting field is Kenteer, a brand synonymous with quality and innovation. Their latest offering, the KTM-A10 DTF Printer, is poised to redefine the possibilities of garment customization. This comprehensive buying guide will delve into the intricacies of the KTM-A10, equipping you with the knowledge to make an informed purchase decision.

Why Choose DTF Printing?

Before we explore the specifics of the KTM-A10, let's understand what makes DTF printing so compelling. Unlike traditional printing methods that often struggle with intricate designs and diverse fabric types, DTF printing delivers exceptional results on virtually any material. Whether it's cotton, polyester, blends, or even dark-colored fabrics, DTF printing ensures vibrant, long-lasting prints that can withstand repeated washes.

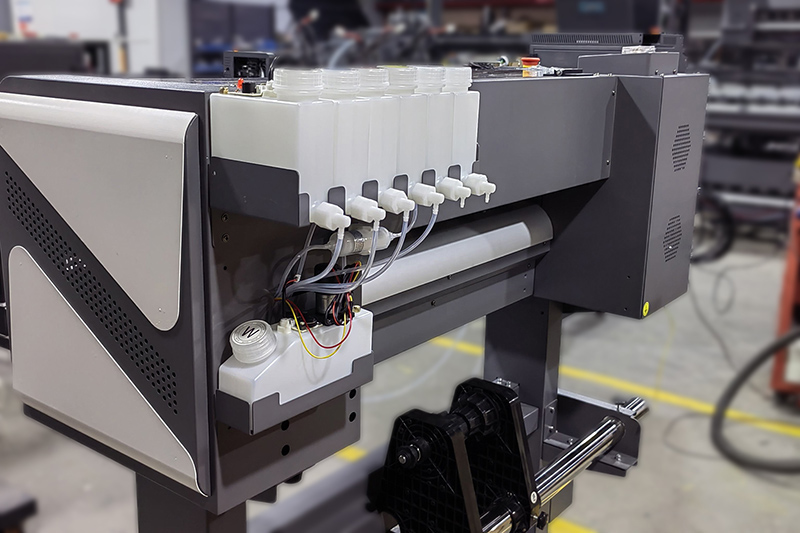

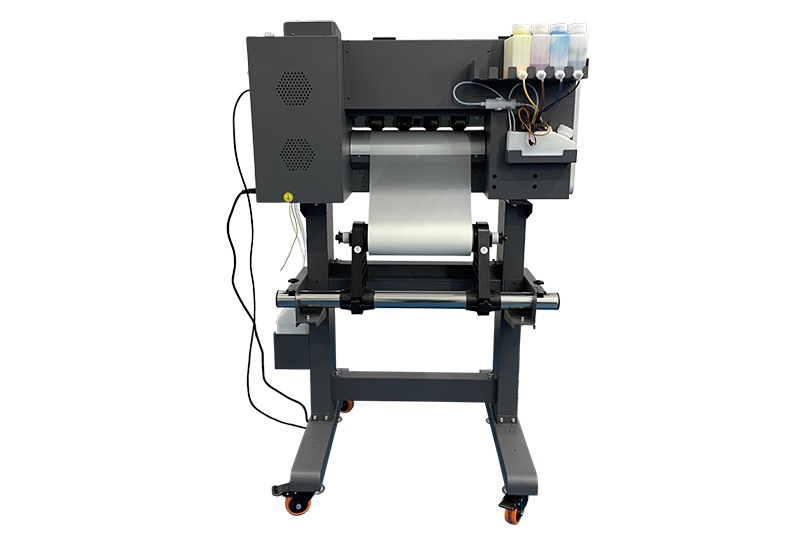

The KTM-A10 DTF Printer embodies Kenteer's commitment to delivering cutting-edge printing solutions. Designed for both startups and established businesses, this printer seamlessly blends user-friendliness with professional-grade performance. Let's explore its key features:

Unmatched Print Quality:

Equipped with dual I3200A1 printheads, including a dedicated HD printhead, the KTM-A10 delivers exceptional print quality with resolutions up to 720*2400 dpi.

Experience vibrant colors, sharp details, and smooth gradients that bring your designs to life.

Choose from 3-pass, 6-pass, or 8-pass printing modes to fine-tune the balance between speed and detail.

Impressive Speed and Efficiency:

The KTM-A10 boasts impressive print speeds, reaching up to 13㎡/h in 4-pass mode.

This efficiency ensures you can handle high-volume orders without compromising on quality.

Three heating sections (pre-heater, printing bed heater, and rear heater) ensure optimal ink curing and prevent issues like ink bleeding.

User-Friendly Operation:

The KTM-A10 is designed for ease of use, featuring a user-friendly interface and intuitive Maitop 6.1 software.

The software is available in both Chinese and English, catering to a global audience.

Manage your printing tasks efficiently with features like print queuing and real-time monitoring.

Versatility and Compatibility:

The KTM-A10 accommodates a maximum printing width of A1/650mm, making it ideal for a wide range of garment sizes and designs.

It supports textile pigment ink in CMYK, white, and fluorescent colors, providing exceptional versatility in design possibilities.

Durability and Reliability:

Kenteer has a reputation for building robust and reliable printing equipment.

The KTM-A10 is built to withstand the demands of a busy production environment.

Its sturdy construction and high-quality components ensure consistent performance and longevity.

Is the KTM-A10 Right for You?

The KTM-A10 DTF Printer is an excellent choice for:

Entrepreneurs: Starting a DTF printing business or expanding your existing service offerings.

Print Shops: Offering customized garment printing to a diverse clientele.

Fashion Designers: Bringing their creative visions to life with high-quality prints.

SMEs: Producing branded merchandise, uniforms, and promotional materials in-house.

The Kenteer KTM-A10 DTF Printer represents a smart investment for anyone looking to capitalize on the growing demand for high-quality garment customization. Its combination of performance, versatility, and ease of use makes it a valuable asset for businesses and individuals alike. With the KTM-A10, you're not just purchasing a printer; you're investing in a solution that empowers you to deliver exceptional results and unlock new levels of creativity in the world of DTF printing.

If you have product purchasing needs, you can contact us.