The world of printing is constantly evolving, with new technologies emerging to meet the ever-increasing demands for high-quality, versatile, and efficient output. Among these advancements, UV printing has taken center stage, offering unparalleled durability, vibrancy, and a wide range of substrate compatibility. The KTM-A47 UV Printer, a new offering from Kenteer, aims to deliver all the benefits of UV printing in a compact, automated, and cost-effective package. This comprehensive buyer's guide delves into the features, benefits, and considerations for purchasing the KTM-A47 UV Printer, equipping you with the knowledge necessary to make an informed investment.

Understanding the Power of UV Printing:

Before diving into the specifics of the KTM-A47, let's briefly explore the advantages of UV printing. Unlike traditional printing methods, UV printing uses ultraviolet light to cure or dry the ink instantly as it's printed. This process offers several key advantages:

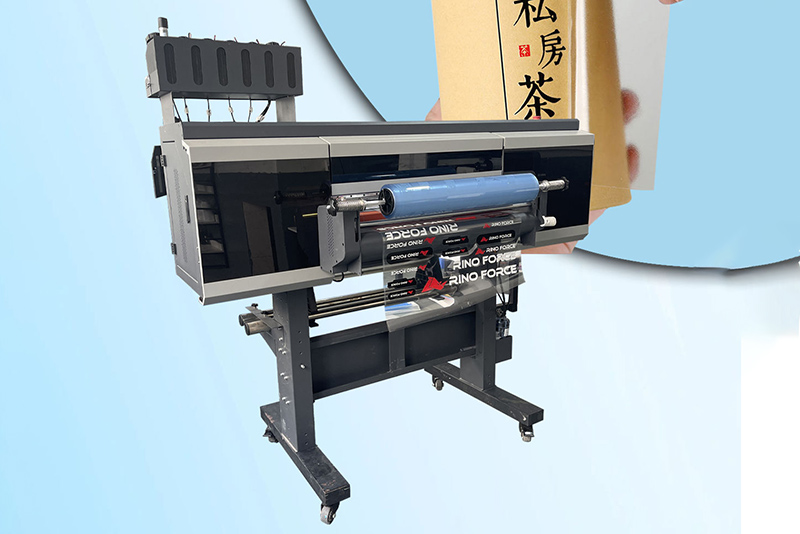

Durability: UV-cured inks are incredibly resistant to fading, scratching, and chemical exposure, making them ideal for outdoor applications and products subject to wear and tear.

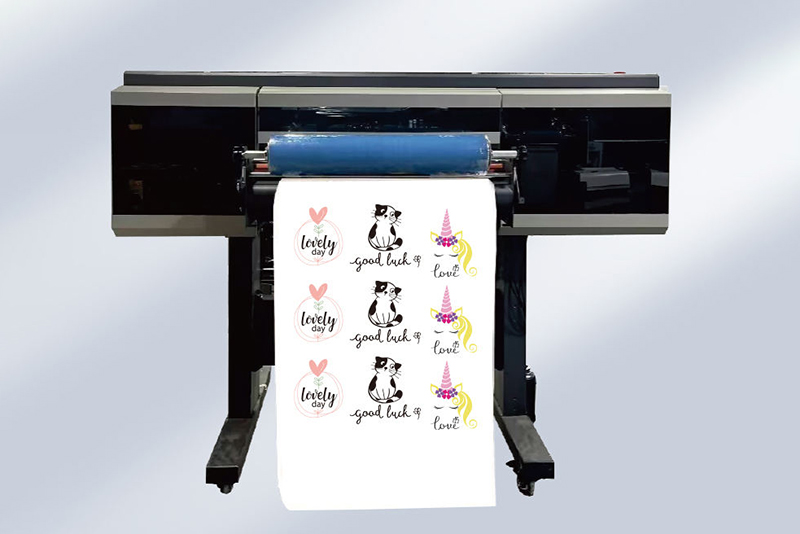

Versatility: UV printers can print on a wide variety of materials, including plastics, metal, glass, wood, and even fabrics, expanding your creative possibilities.

Vibrant Colors: UV inks produce rich, vibrant colors that pop, enhancing the visual appeal of your prints.

Environmentally Friendly: UV inks are generally VOC-free (volatile organic compounds), making them a more environmentally responsible choice.

Fast Turnaround: The instant curing process eliminates drying time, enabling quick turnaround times and increased productivity.

Exploring the KTM-A47 UV Printer:

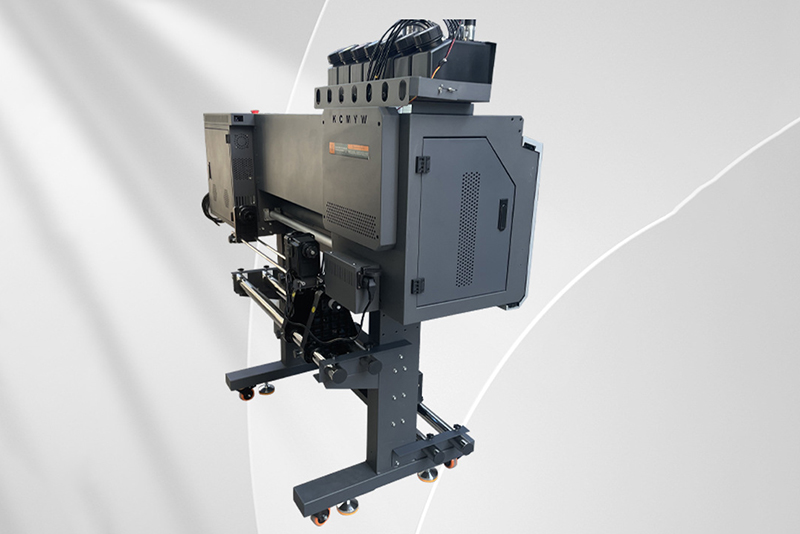

The KTM-A47 UV Printer promises to bring the power of UV printing to businesses of all sizes. This compact and efficient UV printer boasts a range of impressive features:

Printhead Technology: Equipped with four EPSON I3200 U1 printheads, the KTM-A47 delivers high-resolution prints up to 720x2400dpi, ensuring sharp details and vibrant colors.

Versatile Printing Width: With a maximum printing width of 700mm, the KTM-A47 accommodates a variety of print sizes, from small labels to larger format prints.

Automated Features: The KTM-A47 features integrated label printing and laminating, along with rewinding capabilities, streamlining your workflow and boosting efficiency.

Ink Configuration: Supporting CMYK+W and optional 8-color configurations, the KTM-A47 offers flexibility for diverse printing needs, including white ink printing for vibrant prints on dark substrates.

Three Heating Sections: Pre-heater, printing bed heater, and rear heater ensure optimal ink adhesion and curing across various materials.

User-Friendly Software: Compatible with Maitop 6.1, Hoson RUIYIN, and Photoprint software, the KTM-A47 offers intuitive control and ease of use.

Cost-Effective Solution: The KTM-A47 aims to provide a cost-effective UV printing solution without compromising on quality or performance.

Is the KTM-A47 Right for You?

The KTM-A47 UV Printer is a compelling option for businesses looking to leverage the advantages of UV printing. Consider the following factors when evaluating if this UV printer is the right fit for your needs:

Print Volume: While the KTM-A47 offers impressive speed, consider your projected print volume to ensure it aligns with the printer's capabilities.

Application Requirements: Evaluate the types of materials you plan to print on and the desired print quality to ensure the KTM-A47 meets your specific application needs.

Budget: While cost-effective, consider the overall investment, including the cost of the UV printer, inks, and other consumables.

Space Requirements: Factor in the printer's footprint and the required operating environment to ensure you have adequate space and suitable conditions.

Making an Informed Decision:

Investing in a UV printer is a significant decision. Thoroughly research your options, compare features and pricing, and consider consulting with industry experts. Understanding the capabilities and limitations of the KTM-A47 UV Printer , along with your specific business requirements, will empower you to make an informed decision and maximize your return on investment. If you're seeking a versatile, efficient, and cost-effective UV printing solution, the KTM-A47 deserves serious consideration. This UV printer promises to deliver exceptional print quality and unlock new creative possibilities for your business.