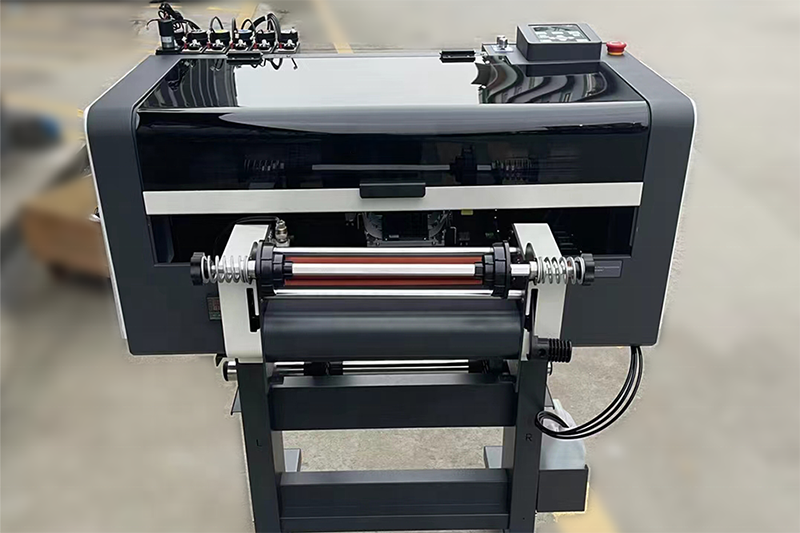

The Kenteer KTM-A48 UV Printer is a robust and versatile machine designed for high-quality printing on a variety of substrates. Boasting advanced features and a competitive price point, the KTM-A48 is a compelling option for businesses looking to expand their printing capabilities. This comprehensive buyer's guide will delve into the specifications, benefits, and considerations surrounding the KTM-A48 UV Printer, equipping you with the knowledge needed to make an informed purchasing decision.

Understanding the Power of UV Printing:

UV printing utilizes ultraviolet light to cure inks instantly upon contact with the printing surface. This process offers several advantages over traditional printing methods, including increased durability, vibrant color reproduction, and the ability to print on a wider range of materials. Whether you're printing on acrylic, wood, metal, glass, or even textiles, a UV printer like the KTM-A48 provides exceptional versatility and print quality. The instant curing process also eliminates drying time, significantly speeding up production and allowing for faster turnaround times.

Key Features of the Kenteer KTM-A48 UV Printer:

The KTM-A48 UV Printer comes equipped with a range of features designed to enhance performance and deliver exceptional results:

Advanced Printhead Technology: The four Epson I3200 U1 printheads deliver precision and speed, producing sharp images with vibrant colors at resolutions up to 720*2400dpi. This high-resolution printing capability makes the KTM-A48 suitable for intricate designs and detailed graphics.

Versatile Ink Configuration: The KTM-A48 supports UV ink and UV pigment ink in CMYK and white configurations, with the option to expand to eight colors. This flexibility allows for a wider color gamut and specialized printing applications.

Efficient Printing Speeds: Achieve print speeds of up to 4.5㎡/h in 6-pass mode, allowing for efficient production runs and maximizing output. The printer also offers 8-pass and 12-pass modes for higher quality and finer details.

Generous Printing Area: With a maximum printing width of 330mm, the KTM-A48 accommodates a variety of substrate sizes, opening up possibilities for diverse printing projects.

Three Heating Sections: Pre-heater, printing bed heater, and rear heater ensure optimal ink adhesion and curing, contributing to the overall print quality and longevity.

User-Friendly Software: Compatible with Maitop 6.1, Hoson RUIYIN, and photoprint software, the KTM-A48 offers intuitive control and seamless integration into existing workflows. The software supports both Chinese and English languages.

Robust Construction: Built with durability in mind, the KTM-A48 UV Printer is designed for long-term performance and reliability.

Why Choose the Kenteer KTM-A48 UV Printer?

The KTM-A48 UV Printer offers several compelling reasons for businesses seeking a versatile and reliable UV printing solution:

Cost-Effective Solution: The KTM-A48 provides a balance of performance and affordability, making it a cost-effective investment for businesses of all sizes.

Enhanced Print Quality: The advanced printhead technology and ink configuration deliver stunningly vibrant and durable prints.

Versatile Substrate Compatibility: Print on a wide range of materials, expanding your creative possibilities and product offerings.

Increased Productivity: Efficient printing speeds and the instant curing of UV inks minimize production time and maximize output.

User-Friendly Operation: Intuitive software and straightforward controls simplify the printing process.

Considerations Before Purchasing:

Before investing in the KTM-A48 UV Printer, consider the following:

Space Requirements: Ensure you have adequate space to accommodate the printer's dimensions and allow for comfortable operation.

Environmental Conditions: Maintain the recommended temperature and humidity levels for optimal printer performance.

Maintenance and Support: Familiarize yourself with the recommended maintenance procedures and available support channels.

Ink Costs and Availability: Factor in the ongoing cost of UV inks and ensure readily available supplies.

The Kenteer KTM-A48 UV Printer presents a compelling option for businesses seeking a versatile, high-quality, and cost-effective UV printing solution. With its advanced features, user-friendly operation, and robust construction, the KTM-A48 empowers businesses to expand their printing capabilities and unlock new creative possibilities. By carefully considering the factors outlined in this buyer's guide, you can make an informed decision and confidently invest in a UV printer that will meet your specific needs and contribute to your business's success. Choosing the right UV printer is crucial for maximizing your printing potential, and the KTM-A48 offers a strong contender in the market.