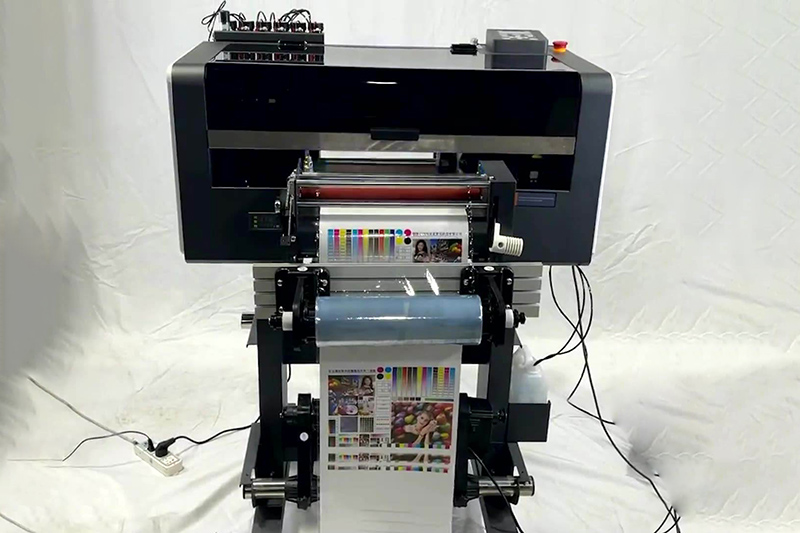

The KTM-A12 UV Printer is a powerful tool capable of producing vibrant, high-quality prints on a variety of substrates. To truly unlock its potential, understanding its features and mastering essential techniques is crucial. This guide provides valuable insights and practical tips for maximizing your printing experience with the KTM-A12 UV Printer.

Understanding the Basics of the KTM-A12 UV Printer:

The KTM-A12 utilizes dual XP600 printheads, delivering precise ink application at resolutions up to 720*2400dpi. Its 300mm printing width accommodates various project sizes, and the adjustable print speed, ranging from 6 to 12 passes, allows for balancing speed and quality. The integrated three-heating system (pre-heater, printing bed heater, and rear heater) ensures consistent temperature control, crucial for optimal ink adhesion and curing. Utilizing UV pigment ink in C/M/Y/K/W/V configuration, the KTM-A12 UV Printer produces vibrant and durable prints.

Pre-Printing Preparation: The Key to Success:

Before initiating any printing job, proper preparation is essential. This includes:

Substrate Selection and Preparation: The KTM-A12 UV Printer’s versatility allows printing on diverse materials, including acrylic, glass, metal, and wood. However, each substrate requires specific preparation. Ensure the surface is clean, dry, and free of dust or debris. For optimal adhesion, consider pre-treating certain materials with a primer specifically designed for UV printing.

File Preparation: High-resolution image files are vital for achieving sharp and detailed prints. Ensure your design files are in a compatible format and optimized for UV printing.

Software Settings: The RIIN printing software provides extensive control over print parameters. Select the appropriate print mode (6Pass, 8Pass, or 12Pass) based on the desired quality and speed. Adjust the ink density and other settings based on the substrate and design.

Printing Process and Optimization:

Print Head Maintenance: Regular print head cleaning and maintenance are essential for preventing clogs and ensuring consistent ink flow. Utilize the automated cleaning function within the RIIN software.

Monitoring Ink Levels: Keep a close eye on ink levels to avoid running out mid-print. The RIIN software provides real-time ink level monitoring.

Temperature Control: Maintaining the recommended environmental conditions (20-28℃ and 65%-75% relative humidity) is crucial for optimal UV ink curing and print quality. Utilize the integrated heating system to ensure consistent substrate temperature.

Ironing (Optional): For certain substrates and applications, ironing can enhance ink adhesion and durability. The KTM-A12 UV Printer offers an ironing temperature range of 45-115℃. Consult the substrate manufacturer’s recommendations for optimal ironing temperature and duration.

Troubleshooting Common Issues:

Banding: Banding, or visible lines across the print, can be caused by clogged print heads, inconsistent ink flow, or incorrect software settings. Cleaning the print heads and adjusting print settings can often resolve this issue.

Poor Adhesion: Insufficient substrate preparation, incorrect ink selection, or inadequate curing can lead to poor ink adhesion. Ensure proper pre-treatment of the substrate and select the appropriate ink for the material.

Color Inaccuracy: Color discrepancies can result from incorrect color profiles, improper software settings, or variations in substrate color. Calibrate the UV printer and utilize appropriate color management tools for consistent color reproduction.

Maximizing the Longevity of your KTM-A12 UV Printer:

Regular Maintenance: Regularly clean the printer, including the print bed, exterior surfaces, and internal components. Follow the manufacturer's recommended maintenance schedule.

Proper Storage: Store the UV printer in a clean, dry environment, away from direct sunlight and extreme temperatures.

Software Updates: Keep the RIIN software updated to benefit from the latest features, performance improvements, and bug fixes.

By understanding the intricacies of the KTM-A12 UV Printer and implementing these practical tips, you can unlock its full potential and produce stunning, high-quality prints on a variety of substrates. This powerful UV printer, when used correctly, can elevate your printing projects to a professional level. Remember to always refer to the user manual for detailed instructions and safety precautions. Mastering these techniques will transform your printing workflow and allow you to fully leverage the capabilities of your KTM-A12 UV Printer.