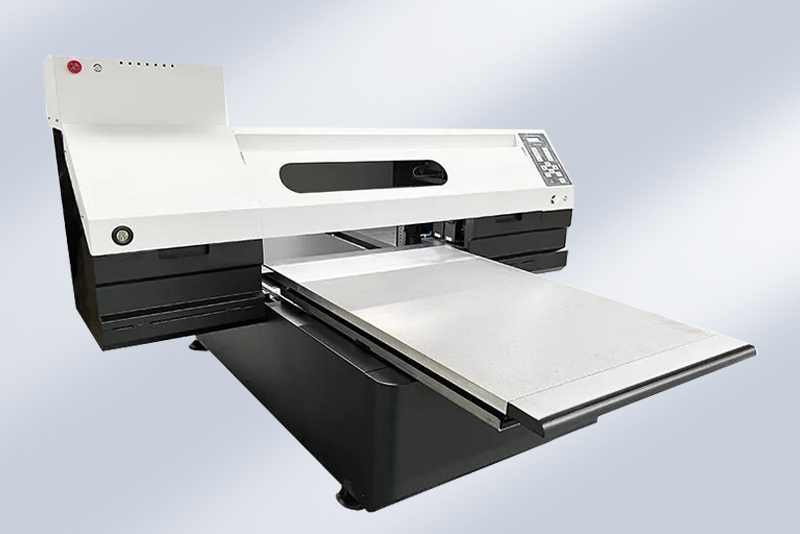

The KTM-A14 multifunctional UV flatbed printer represents a significant advancement in the rapidly evolving landscape of digital printing. This powerful machine, developed by Kenteer, offers a compelling combination of speed, versatility, and precision, making it a valuable tool for businesses seeking to capitalize on the growing demand for customized products. This analysis will explore the current market applications of the KTM-A14 UV flatbed printer, delve into future technological trends within the UV flatbed printer sector, and highlight the key features that position the KTM-A14 for continued success.

Currently, the market for UV flatbed printers is experiencing robust growth, driven by the increasing desire for personalized goods and on-demand printing solutions. The KTM-A14 UV flatbed printer is well-suited to address these market needs, offering a wide range of applications. Its ability to print directly onto various substrates, including wood, metal, acrylic, glass, and even phone cases, opens doors for businesses in diverse sectors. Sign makers, promotional product companies, and industrial manufacturers can leverage the KTM-A14 to create high-quality, customized products with vibrant colors and durable finishes. The inclusion of varnish printing further enhances the aesthetic appeal and protective qualities of printed materials.

The KTM-A14's impressive specifications contribute to its versatility and productivity. With a print area of 600x900mm and the capacity to handle materials up to 180mm thick, it accommodates a wide variety of product sizes and shapes. The dual i1600-U1/i3200-U1 or triple i1600-U1 print head options, combined with dual UV LED curing lights, ensure efficient and high-resolution printing, reaching up to 2400 dpi. The ability to print an A2 sheet in as little as 5 minutes significantly boosts productivity, allowing businesses to meet tight deadlines and fulfill large orders efficiently. The integrated color siphon and regular white ink mixing system further enhance the printer's performance, ensuring consistent color accuracy and minimizing ink waste.

The future of UV flatbed printing technology promises even greater advancements. We can expect to see continued improvements in print head technology, leading to faster print speeds, higher resolutions, and enhanced color gamuts. Furthermore, the development of new inks with specialized properties, such as increased flexibility and adhesion to challenging substrates, will expand the range of printable materials and applications. Integration with automation and robotics is another key trend, enabling seamless workflow integration and further boosting productivity. Advancements in software and RIP technology will streamline the printing process, simplifying complex designs and improving color management. The industry is also moving towards more eco-friendly practices, with the development of UV inks with lower VOC emissions and energy-efficient curing systems.

The KTM-A14 UV flatbed printer is well-positioned to capitalize on these emerging trends. Its robust construction, advanced features, and adaptable design make it a future-proof investment for businesses seeking to stay ahead of the curve. The Gigabit Ethernet interface ensures seamless integration with modern networks and workflow management systems. The printer's relatively compact footprint and manageable weight also contribute to its practicality, making it suitable for a variety of production environments.

The market for personalized and customized products is experiencing unprecedented growth. The KTM-A14 UV flatbed printer empowers businesses to tap into this market by offering a powerful and versatile solution for direct-to-object printing. Its ability to handle a wide range of substrates, combined with its high print quality and speed, makes it a valuable asset for businesses across various industries. As UV flatbed printing technology continues to evolve, the KTM-A14 stands as a testament to innovation, offering a glimpse into the future of customized printing. The demand for UV flatbed printers, like the KTM-A14, will only continue to increase as businesses seek to differentiate themselves through personalized products and on-demand printing capabilities. This dynamic market offers significant opportunities for growth and innovation, and the KTM-A14 UV flatbed printer is poised to play a key role in shaping the future of the industry. Its combination of advanced features, robust performance, and adaptability makes it a compelling choice for businesses seeking to invest in a cutting-edge UV flatbed printer solution.